Expansion Joints for piping systems are flexible connectors which are made out of PTFE, natural or synthetic elastomers, with combination of rubber, fabric and metal reinforcement. Expansion joints installed into piping, systems will help solve problems like –

Stresses –Expansion joints can absorb movement due to thermal expansion and contraction of pipes, wear, load stresses and settling of supports and foundations.

Misalignment – Expansion joints are often manufactures with offsets to account for installation error in pipe alignment, or for movement and settling over time.

Abrasion – Abrasion can be significantly reduced compared to other rubber or metallic connectors.

Vibration – Vibration can be significantly reduced by expansion joints when installing in proper locations and are not subject to metal fatigue failure.

Noise – Expansion joint acts as a dampener and absorbs the noise level and this can reduce transmission of sound.

Shock – Effects of pressure surges, water hammer, or pump cavitations are resisted

Corrosion – No metal to metal contact eliminating electrolysis between dissimilar metals

Space – Greatly reduced space required compared to expansion bends or loops

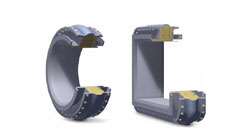

Rubber Expansion Joints are a flexible connector fabricated from natural or synthetic elastomers and fabrics with metallic reinforcements designed to provide stress relief in piping systems due to thermal changes. When flexibility for this movement cannot be designed into the piping system itself, an expansion joint is an ideal solution. Rubber expansion joints compensate for lateral, torsional and angular movements preventing damage and undue downtime of plant operations. The special construction of the rubber joints can solve problems such as –

Fabric expansion joints are a vital component in most industrial plants. They are installed as flexible connections in duct and piping systems to take up or compensate for thermal expansion, vibration or misalignment. Selection of the perfect expansion joint for your system is important for ensuring reliable operation. A properly designed and installed expansion joint can ensure uninterrupted plant performance between scheduled maintenance shutdowns.

Advantages –

By combining different materials and taking into consideration the thermal, chemical and mechanical resistance as well as the fatigue properties of the material, our designers provide optimum solutions both technically and economically.