CNC which stands as the short form for “computer numerical control” is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. Three-dimensional cutting tasks can be accomplished in a single set of prompts that can be accomplished with CNC machining.

The CNC process runs in contrast to and thereby supersedes, the limitations of manual control, where live operators are needed to prompt and guide the commands of machining tools via levers, buttons, and wheels. By the looks, a CNC system resembles a regular set of computer components, but the software programs and consoles employed in CNC machining distinguish it from all other forms of computation.

With the activation of a CNC system, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much in similarity with a robot.

Lasers are used for various purposes, cutting of metal plates is one significant use. On mild steel, stainless steel, and aluminum plate, the laser cutting process is highly accurate, yields excellent cut quality has a very small kerf width and small heat-affected zone and makes it possible to cut very intricate shapes and small holes. The laser beam is a column of very high-intensity light of a single wavelength or color. The beam is only around ¾ of an inch in diameter as it travels from the laser resonator, which creates the beam, through the machine’s beam path. Before being finally focused onto the plate, it may be bounced in a different direction by a number of mirrors. Right before hitting the plate, the focused laser beam goes through the bore of a nozzle along with a compressed gas like Oxygen or Nitrogen.

Focusing the laser beam can be done by a special lens, or by a curved mirror, and this takes place in the laser cutting head. The beam has to be precisely focused so that the shape of the focus spot and the density of the energy in that spot are perfectly round and consistent, and centered in the nozzle. The high power density results in rapid heating, melting and partial or complete vaporizing of the material.

Dutco Tennant LLC is a well-known company for supplying a wide variety of industrial and engineering products in the Middle East and GCC region.We specialize in supplying :

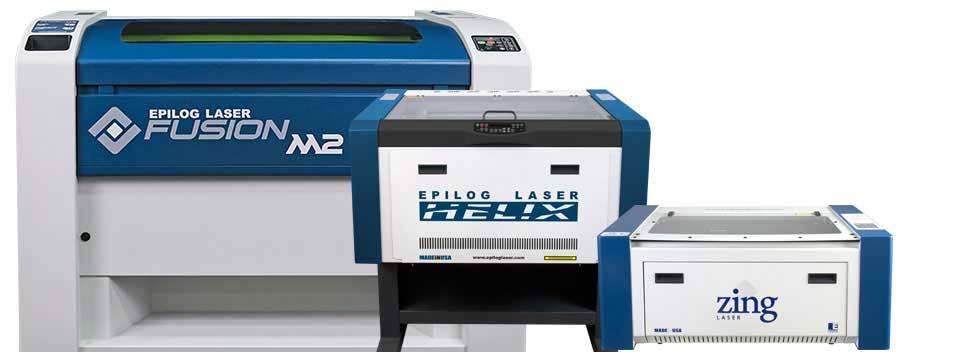

- CNC Machines

- Laser Cutting Equipment

- And MORE