Plug Valves are quarter turn valve, which is useful where quick and frequent operation is essential. They are available in various material of construction like Carbon Steel, Stainless Steel, Exotic Steel Material.

Plug Valve have three general categories & they are Lubricated Plug Valve, Non Lubricated (Teflon Sleeved) Plug Valve & Expanding Plug Valve

Plug Valves are used in many industrial applications including Petrochemical, Oil & Gas, Pipelines, Power, Tank Farms, Allied process and also services such as corrosive and cryogenic.

Teflon Sleeved Plug Valve

Teflon Sleeved Plug Valve (Ansi Classes 150 300)

Construction

- Size : 1/2” to 24”

- Rating : ANSI Classes 150 - 300

- Bi- Directional, Cavity Free Passage

- Positively Locked Sleeve ensuring zero Leakage

- Low pressure Drop across the Valve

- Self Lubricated

- Design Std: API 599, Testing Std: API 598

- Face to Face as per ANSI B 16.10

- Fire Safe as per API607

- End Connection : Flanged Drilling as per ANSI B 16.5, RF Serrated

- Lever/ Gear Operated

- API 6D Design

- Face to Face as per DIN Standard

- Locking Arrangement

- Extended Spindle

- Pneumatic/ Hydraulic/ Motor Operated

- Caged Valve/ 3-way/ Jacketed Valves

- Other End Connection Screwed / Socket Weld Ends (up to Size: 2”)

- All Exotic Materials (Hastelloy/ Incoloy/ Super duplex) & PFA Lined

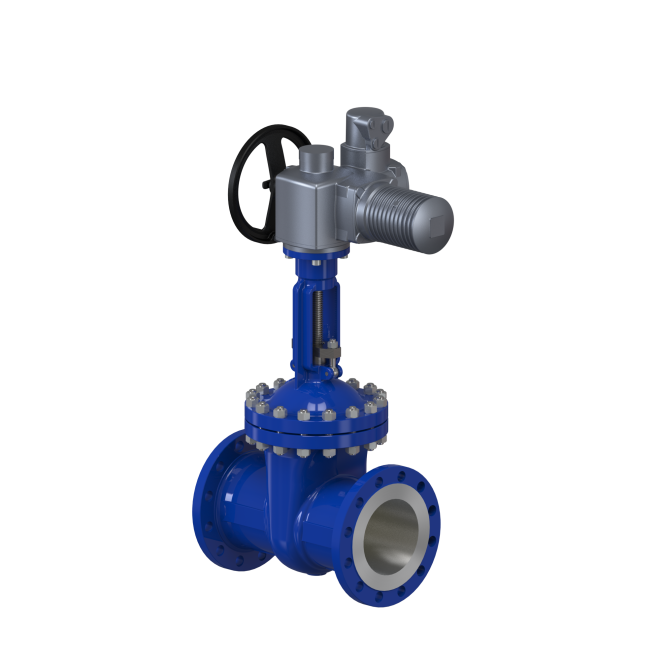

Pressure Balance Lubricated Plug Valve

Construction

- Size : 2” to 24”

- Rating : ANSI Classes 150 - 1500

- Emergency Stem Seals for assured Sealing

- Cavity Free Construction

- Low pressure Drop

- Blow out Proof Stem

- Design Std: API 6D, Testing Std: API 598/ API 6D

- Face to Face as per ANSI B 16.10

- End Connection : Flanged Drilling as per ANSI B 16.5, RF Serrated

- Lever/ Gear Operated

- Fire Safe as per API 6FA/ API RP 6F

- Design as per Short/ Venturi/ Regular Pattern

- Sealant Injection Arrangement

- Pneumatic/ Hydraulic/ Motor Operated

- High/ Low Temperature Services

- Other End Connection: RTJ/ BWE

- All Exotic Materials (Hastelloy/ Incoloy/ Super duplex)

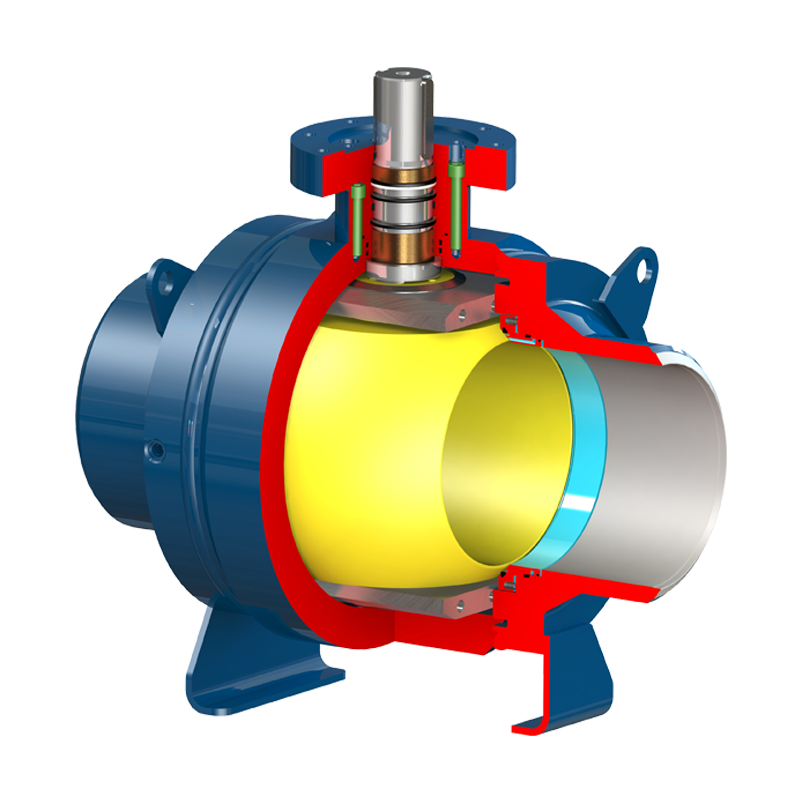

Expandable Plug Valve

Double Block & Bleed Expandable Plug Valve

Construction

- Size : 1/2” to 42”

- Rating : ANSI Classes 150 - 900

- Expandable Plug Type, Reduced / Full Port

- Tight Shut-off Zero Leakage

- Double Block & Bleed

- Non Lubricated Seals

- Design Std: API 6D, Testing Std: API 6D/ API 598

- Face to Face as per ANSI B 16.10

- Fire Safe as per API607/ API 6FA/ BS 6755 Part-2

- End Connection : Flanged Drilling as per ANSI B 16.5, RF Serrated ANSI B 16.47 Series A/B for Sizes above 24”

- Handwheel/ Gear Operated

- Face to Face as per DIN Standard

- Locking Arrangement

- Extended Spindle

- Pneumatic/ Hydraulic/ Motor Operated

- Low Temperature/ Cryogenic Services

- ATEX

- Other End Connection

- All Exotic Materials

Material of Construction

- Body : DI/ WCB / WCB+ENP/CF8/ CF8M / Duplex

- Plug : DI/ WCB/ WCB+ENP / CF8/ CF8M / Duplex

- Stem : SS410/ SS304/ SS316/ Duplex/ ASTM A564 630 (17/4PH)

- Sleeve : PTFE/ GFT

- Slip : ASTM A 536 80-55-06 (DBB Plug Valve)

- Seals : NBR/ Viton/ FFKM (DBB Plug Valve)