Equipment and systems for vocational qualifications and engineering education on the following topics :

Power electronics & Drive technologySubjects :

- Power electronics

- Power electronics and drives 300W

- Designing drive controllers 300W

- Industrial drive technology 300W

- Power electronics and didactically-optimized drives 1kW

- Designing drive controllers 1kW

- Industrial drive technology 1kW

- Equipment sets for practical training

Power Electronics

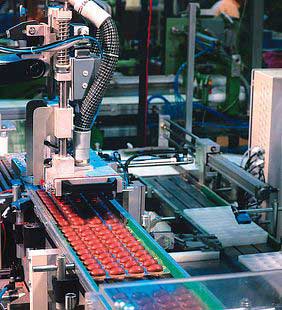

The multimedia courses in power electronics use numerous experiments and animations to explain the design and function of various types of converters. Students taking the courses are familiarized with the various types of power semiconductor devices and become familiar with the common circuits in which they are used. Different types of circuits are used in a large number of experiments that deal with triggering, modulation and instrumentation involving millimeters and oscilloscope as well as deriving the properties and capabilities of converters.

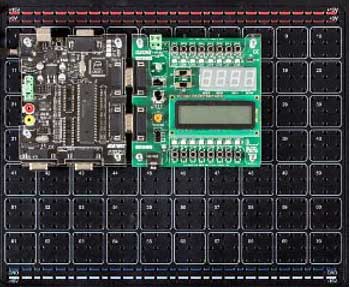

Designing Drive Controllers

Drive Controllers enables rapid prototyping of embedded open-loop and closed-loop control systems. System designs can first be investigated using a PC simulation. Then the next step is to apply the design to real hardware and test it. This kind of simulation-based learning is motivating and interesting to students.

It enables drive systems, which are capable of operating in real time, to be programmed and tested using the model-based design methods used in industry.

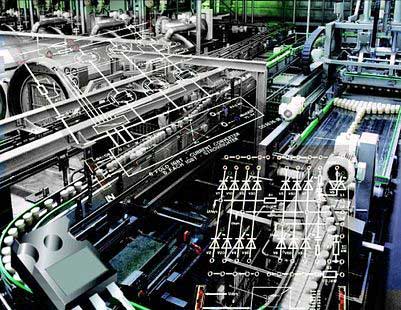

Industrial Drive Technology

Today's industrial world is no longer conceivable without controllable electrical drives. Their area of application ranges from special high power drives to vehicle powering, machine tooling and production machines and includes automotive applications. In addition to the machines themselves, it is power electronics in conjunction with automation, automatic control engineering and bus technology which are having such a great impact on the drive's response and operating possibilities.

Unlike didactically-modified drives, this training equipment incorporates industrial components. Thus the system focuses on the handling and operating (setting parameters) of real industrial equipment. Using the servo drive/braking system the response of the drives can be investigated dynamically and statically and using different working machines. The equipment is designed in the form of training panels.