SELECTING THE RIGHT RUBBER EXPANSION JOINT FOR YOUR NEEDS

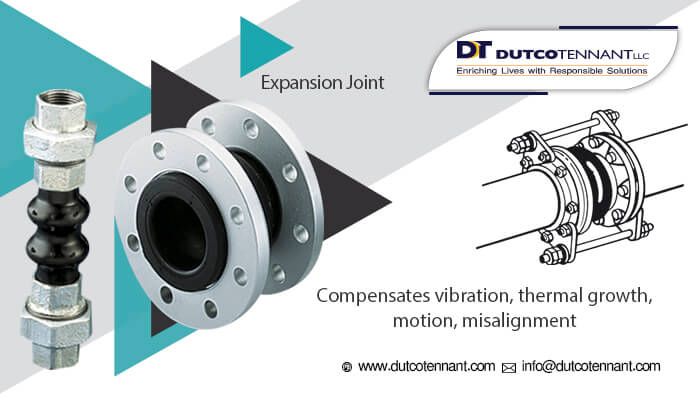

Rubber Expansion Joints have been targeted towards absorbing the anticipated piping movements or displacements, reducing the vibration and noise, and also have a life cycle in the tens of millions. They also atone for the misalignments, offer access to the piping and equipment, and relieve the stresses in anchors and pipes. The main function of these is their ability for absorbing the fluctuating thermal or external movements in a ridged piping system and exchanging or replacing the occasional catastrophic effects of these stresses with the extremely low spring rate or stiffness of the rubber expansion joint. For making your selection from the several types of rubber expansion joints, it will be easier by dividing the proposed piping sections into individual sections by selecting the tentative anchor locations. If an individual section is perfectly anchored and guided, then an undertrained rubber expansion joint style will represent a cost-effective optimal arrangement.

If an individual section comes with limited support structure or has limitations regarding load on the adjacent equipment, and then choosing from the restrained rubber expansion joint style often offers the most effective solutions. The pressure thrust forces inside the piping system are much better managed by the restrained styles restrain. Once, every section gets optimized by taking advantage of a given style, it then can be easily incorporated back into the entire piping system. This iterative approach may need some additional design considerations including the capabilities and limitations of several rubber expansion joint styles. The design of the unstrained rubber expansion joints has been made for absorbing all the directional movements in well-guided, well-anchored piping systems. They have a spool-type body that is often constructed with complete rubber flanges, multiple layers of high-strength tire cord, a high-grade leak-proof tube, a seamless cover, high tensile steel reinforcement, and galvanized retaining rings. A standalone expansion joint when is used in rigid piping systems represents the most cost-effective arrangement with main anchors and several guides at specific spacing. The control units can be internally or externally attached and used as limit rods for secondary restraint.

Universal Rubber Expansion JointsThis expansion joint type has two resilient arch sections which have been separated by a straight section for facilitating higher lateral movement capability. This single unit arrangement is a highly effective solution for absorbing axial thermal movements from the adjacent pipe runs, The spool-type body is occasionally constructed with complete rubber flanges, multiple layers of high-strength tire cord, high-grade leak-proof tube, high tensile steel reinforcement, galvanized retaining rings and a seamless cover. The control units are internally or externally attached and are used as limit rods for secondary restraint in a completely anchored piping system or as tie rods when the support structures and adjacent equipment are having load limitations.

Hinge Rubber Expansion JointsThese joint types have been designed for facilitating and isolating angular rotation in a single plane. This arrangement comprises a pair of hinge plates that care connected by pins and are attached to the expansion joint’s external or internal hardware. The hinge assembly needs to be designed for the internal pressure thrust forces of the system. They can be used in sets of three or two for absorbing large lateral movements from an adjacent pipe run. The spool-type body is constructed occasionally with full rubber flanges, a high-grade leak-proof tube, multiple layers of high-strength tire cord, high tensile steel reinforcement, and a seamless cover. These are mainly used when the support structure or adjacent equipment comes with load limitations. The economic benefits of this arrangement include a smaller system footprint with very few anchors and guides.

Gimbal Rubber Expansion JointsThis type of design mainly isolated and facilitates angular rotation in two planes. The arrangement comprises two pairs of hinge plates which are connected with pins to a common gimbal ring and is attached to the external or internal hardware of the expansion joint. The assembly of the gimbal needs to be designed for the internal pressure thrust forces of the system. They can be used in sets of two or sets with a hinge design for absorbing large lateral movements in several planes.

Dutco Tennant LLC can supply you with a modified range of Rubber Expansion Joints for plumbing which can be used for several plumbing projects. These have been designed and manufactured by WATTS and offer you qualified performance every time.