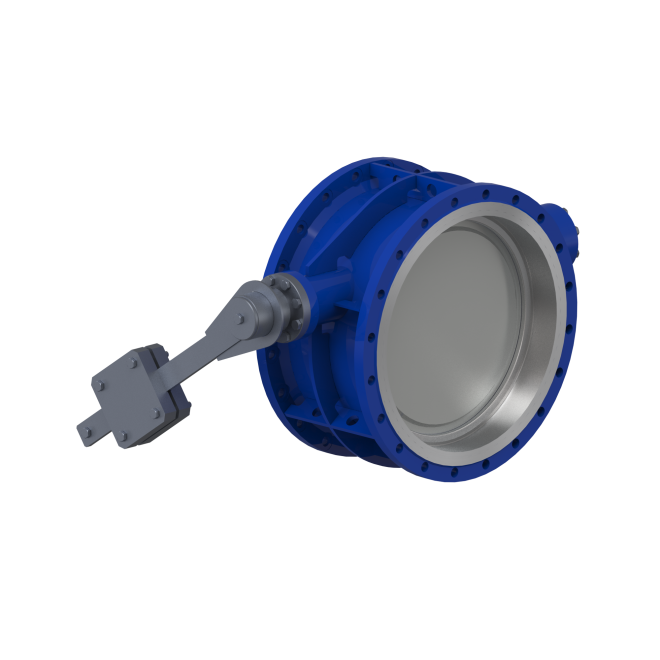

Our Butterfly Swing Check Valve is the perfect solution for preventing backflow and ensuring smooth operations in your pipeline systems. Our self-acting and fast-closing valves are specifically designed to prevent working mediums from flowing back in your pipelines. They are ideal for use in preventing backflow in pumps, fans, and other similar equipment.

While our check valves are not shut-off valves, they offer a quick-acting, automatic solution that keeps your pipeline systems running smoothly. The valves feature an eccentrically embedded valve disc that rotates inside a flanged end fabricated body. The shaft is clamped in self-lubricated friction bearings and comes with a lever with a counterweight on the end. The movement of the disc is controlled by the flowing fluid, which makes it a quick-acting valve.

One of the best things about our butterfly swing check valves is their versatility. They can be mounted into horizontal, vertical, or inclined piping. When mounting in a horizontal piping, simply ensure that the arrow on the valve stamped in the valve body corresponds to the flow direction of the working medium, and the valve disc rotation axis is in a horizontal position and above the axis of flowing. If mounting in a vertical piping, the working medium will have to flow upwards.

Our butterfly swing check valves offer a range of advantages, including low pressure loss, a fabricated design that allows for flexibility, maintenance-free operation, and long service life. Additionally, their one-piece body and design variability make them a great option for a range of applications. Furthermore, the design of our valves helps to minimise water hammer.

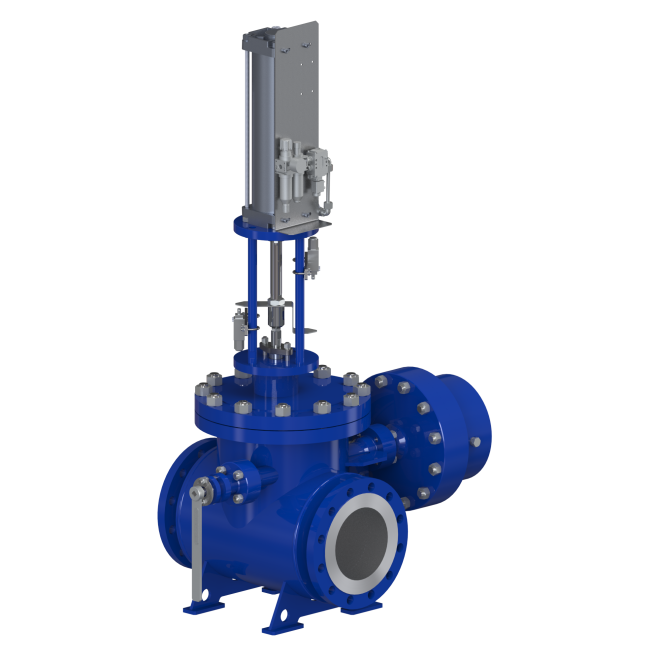

We at Dutco Tennant LLC also distribute Extraction Check Valves from Armatury Group. These valves are a crucial component used in steam turbines to prevent backflow of service fluid in extraction and bleed lines.

Our Extraction Check Valves are designed to meet the specific extraction parameters for each individual application, ensuring maximum efficiency and reliability. These valves are designed to handle high-temperature applications, with a maximum service temperature of up to +450°C for DN 1000 and NPS 40, and up to +350°C for above DN 1000 and NPS 40.

The Extraction Check Valves are designed as check valves with double eccentricity. The disc with a conical sealing surface swings on a shaft, which is carried in plain bearings. When in the "CLOSED" position, the disc's sealing surface comes in contact with the valve body seat, preventing any backflow. Our valves are designed with a counterweight to balance the disc's mass, which guarantees minimum pressure losses of not more than 1%. The counterweight is located in a separate pressure-closed box, off the valve body bore.

Our Extraction Check Valves are designed with a welded construction that meets the requirements of EN ISO 15614-1, PED 2014/68/EC or, if required by the customer, ASME CODE, Section IX.