Dutco Tennant LLC is one of the leading suppliers of seismic protection devices and solutions for almost over 40 years in the Middle East and GCC region. Our solutions and products have been developed after several researches by various experts. Bridge Bearings and Expansion Joints are very important elements in large infrastructures such as bridges. Bridge bearing ensures load transfer, movement, rotation, vertical or horizontal restraints as required by the design at critical locations in a bridge. Reinforced elastomeric bearings and pot bearings are the most widely used structural bearings. Dutco Tennant LLC has the capability to supply fully integrated bearings, which can be "tailor-made" to meet different design requirements for rotations, restraints, loading, movements, and other requirements. Dutco Tennant has provided Bridge Bearings and Expansion Joints for several prestigious projects in the Middle East and GCC. In the past, Dutco Tennant LLC has supplied solutions for many high profile projects such as Dubai International airport expansion, Dubai parallel Roads, etc. We can provide you more project reference at request. Dutco Tennant LLC has complete knowledge of different project requirements in the Gulf region and therefore we can provide the best solution.

Spherical bearings are manufactured in a wide variety of materials and are designed to offer bearing solutions in almost any operating environment. Dutco Tennant LLC offers a wide range of spherical bearings which are available in inch and metric. The high-quality spherical bearings offered by us are suitable for heavy-duty, off-highway vehicles, agricultural equipment, construction and mining and logging equipment, packaging and textile equipment, and robotics. Spherical Plain Bearings comes with an inner ring with a sphere convex outside surface and an outer ring with a corresponding sphere, but concave inside surface. They are made particularly suitable for bearing arrangements where alignment movements between shaft and housing have to accommodate because of their design, or in places where oscillating or recurrent tilting movements must be permitted at relatively slow sliding speeds.

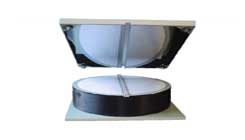

Our Spherical Bearings are designed to carry combinations of vertical loads, horizontal loads, longitudinal and transversal movements and rotations and they are used in steel and concrete road and railway bridges. The bearing is composed of steel elements coupled with PTFE surfaces to allow movement and rotations. One side of the internal median plate is machined as a spherical surface to allow tilting movement (rotation) whilst on the other side, a flat sliding surface is obtained to allow displacements. Depending on whether the bearing is fixed, guided sliding or a free sliding, they accommodate vertical loads and corresponding horizontal forces, as well as movements in longitudinal or transversal directions.

Quality of the Materials

- Austenitic Steel Sheet : The austenitic steel used for sliding surfaces is X5CrNiMo17-12-2 in accordance with EN 10088-2 1.4401 with a minimum thickness of 1.5 mm The roughness is Ry5i ≤ 1 μm The hardness ≥ 150 HV1 and ≤ 220 HV1

- Ptfe : These bearings use only virgin PTFE without regenerated or filler materials. The minimum thickness of PTFE is 4.5 mm and varies in according with the bearings size.

- Ferrous Material For And Piston : The piston and if applicable the sliding plate are manufactured from ferrous material in accordance with EN 10025 standard.

- Concrete Pressure : According to EN 1337-7 the allowable concrete pressure depends on the relative dimensions of the bearing structure interface to the total support area and the characteristic strength of the concrete.

Load Combinations

Spherical Bearings can carry very high loads, over 100.000 kN The bearings are designed for combined maximum vertical and horizontal loads. The standard range of bearing is designed to have an horizontal load ≤ 15% of the maximum vertical load with a maximum rotation of ± 0.02 rad (other load and rotation combinations are provided on request).In order to define the correct bearing, our engineers take into account the designed load effects, rotations, displacements and type of fixings.

Specifications

- FRICTION OF THE BEARINGS :

The reaction of the bearing to the movement can be mathematically calculated by considering friction coefficient between stainless steel and PTFE, the design friction values are in according to EN 1337-2 section 6.7.

- MOVEMENT INDICATOR :

The movement indicator allows the monitoring of the sliding bearing displacement by using a reference arrow fixed to the bearing base and a graduate indicator moving with the sliding plate. The movement indicator allow to check the initial presetting of the bearing (if required) and to verify the bearing motion during the future inspections.

- DUST PROTECTION :

The dust protection around the sliding plate ensure the cleaning of the sliding surfaces to minimize the friction during sliding and guarantee the durability of the PTFE sliding material.

- CORROSION PROTECTION :

Steel components exposed to the elements are protected against corrosion. Agom adapts the corrosion protection in accordance to the aggressiveness of the environment in which the bearings are to be installed and to each customer’s requirements. The standard corrosion protection according EN 1337-9 is as follows: - sandblasting SA2.5 grade - two components high thickness epoxy zinc paint: 250 µm The high resistant corrosion protection (metallization) is as follow: - sandblasting SA 2.5 grade - metal spraying to 85 µm with Zn/Al 85/15 - sealing: Epoxy sealer 20-25 µm - top coat: Polyurethane paint 100 µm