Duckbill valves are unique, one-piece, elastomeric components which act as backflow prevention devices or one-way valves or check valves. They consist of elastomeric lips in the shape of a duckbill which prevents backflow and allows forward flow. The main advantage of duckbill valves over other types of one-way valves is that these valves are self-contained which means that the sealing functionality is an integral part of the one-piece elastomeric component as opposed to valves where a sealing element has to engage with a smooth seat surface to form a seal. So for this, duckbill valves are easily incorporated and assembled into a wide variety of devices without the hassle or problems associated with the surface finish quality of mating seats and/or complex assembly processes.

Rubber Duckbill Check Valves and Inline Rubber Check Valves are an exceptionally reliable and cost-effective method for controlling back pressures in sewage treatment plants. Other common applications are stormwater outfall, effluent discharge, flood control, wet wells. These valves are fully passive flow devices that require absolutely no maintenance whatsoever, no source of power or manual operating assistance, and are an excellent alternative to conventional flap gate valves and other check valves. The flexible Rubber Duckbill Valve is normally closed but will open with very minimal head pressure, always providing maximum flow with a minimal pressure drop across the valve. Conventional Flap-Gate Check valves and other check valves are mechanical and have metal components which are commonly known to malfunction, rust and seize. Rubber Duckbill Check Valves can also handle large obstructions without jamming or binding, and guarantee trouble-free backflow prevention and can even seal around trapped or suspended solids with minimum backpressure. The finest of engineering elastomers are used, and the outer layers, are designed to repel marine organisms.

Duckbill Check Valves flexible sleeve design made of quality fabric-reinforced elastomer materials for maximum resistance to corrosion and wear caused by continuous operation with abrasive slurries, sludge, or effluent. A maximum flow with a minimum pressure drop across the valve at all times is provided by the flexible sleeve. Duckbill check valves have been in use for over 100 years and are commonly considered for use in waste and stormwater or sewer piping systems.

Dutco Tennant has been serving the wastewater industry of the Middle East and GCC region for more than four decades with exceptional solutions that meets all the regulatory standards. With us, you can be assured to always get the best solutions and the best possible price.

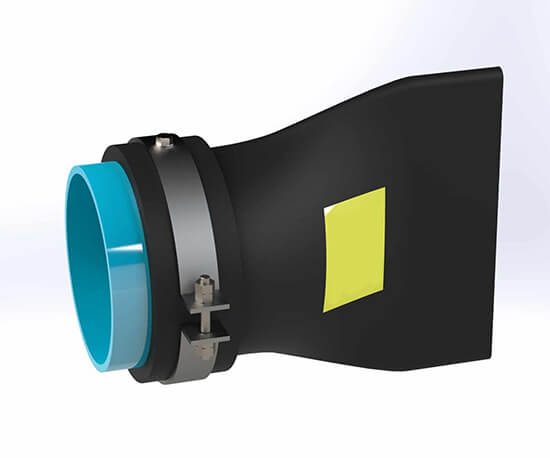

Duckbill Check Valves for Wastewater Outfalls and Diffusers

Duckbill Valves / Series 700 ProFlex™ Rubber Check Valve