For large infrastructures such as bridges, Bridge Bearings, and Expansion Joints are very important elements. Dutco Tennant LLC has the capability to supply fully integrated bearings, which can be "tailor-made" to meet different design requirements for rotations, restraints, loading, movements, and other requirements. Dutco Tennant LLC provides these different bride bearings: Elastomeric bridge bearings for small and moderate loads, Pot bearings for greater loads, Spherical bearings, for high loads and high rotation requirements.

Bridge Elastomeric bearing pad is typically made of a strong and pliable material such as neoprene – a type of heavy-duty industrial rubber. They are placed in between superstructures such as the bridge beam and substructures such as the vertical supports called piers. The primary function of these bearing pads is to distribute superstructure loads to the substructure and allow the superstructure to undergo necessary movements in irregular environmental conditions without creating any harmful stresses that might compromise the structural integrity of the bridge. When the structural integrity of the bridge is compromised, the bridge could collapse.

But preventing the collapse of the bridge is not the only function of an elastomeric bearing pad. The pad extends the life of bridges by reducing wear and tear on bridge materials. The pad helps to save money by delaying the replacement of bridges, just like the way shoes allow human beings to walk long distances.

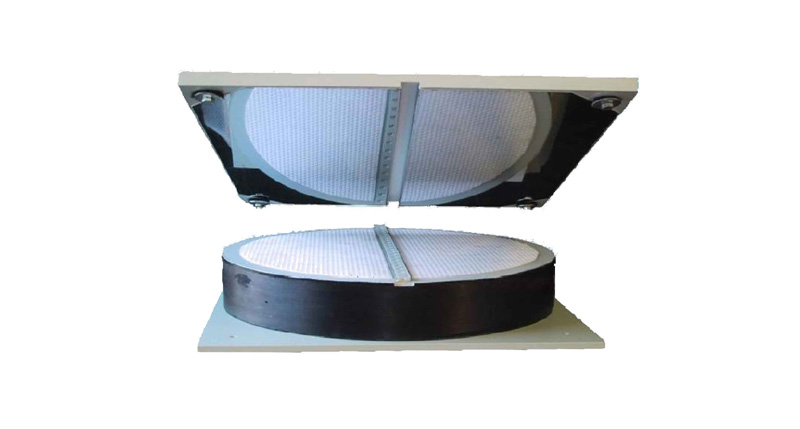

Laminated elastomeric bearings support simultaneous loads and deformation in any direction. Steel plates are bonded to the rubber through a vulcanization process and have the main scope to increase the resistance of the bearings to vertical loads. The steel plates are fully embedded in the elastomer so that they are protected against corrosion. The connection of the elastomeric bearings to the structure may be through the rubber itself or steel elements of various shapes suitable for any kind of structure. Horizontal movements up to approximately one half of the rubber thickness and rotations are allowed by the flexibility of the rubber. Higher horizontal movements can be reached utilizing the rubber bearings with PTFE.

Our Elastomeric bearings are built to withstand loads and simultaneous deformation in any direction, while also allowing for minor rotations in any of the bearing's axes. These bridge bearings can be made entirely of rubber or can be reinforced with special sheet steel to increase capacity and transversal strength. Bearings can also be produced with special anchor plates or with sliding surfaces to improve the structure's displacement capacity. This kind of bearing can withstand vertical loads of up to 22000 kN.

Advantages

- Transmit the vertical loads due to permanent and accidental effects; it is possible to cover a wide range of loads about up to 22000 kN

- Transmit the horizontal loads with or without elastic response

- Allow rotation as per a spherical hinge

- Capacity of horizontal displacement

- Suitable for all structures steel and concrete bridges and buildings f. High durability and no maintenance

Quality of Materials

- AUSTENITIC STEEL SHEET :

The austenitic steel used for sliding surfaces is X5CrNiMo17-12-2 in accordance with EN 10088-2 1.4401 with a minimum thickness of 1.5 mm. The roughness is Ry5i ≤ 1 μm The hardness ≥ 150 HV1 and ≤ 220 HV1

- FERROUS MATERIAL FOR POT AND PISTON :

The pot, the piston and if applicable the sliding plate are manufactured from ferrous material in accordance with EN 10025 standard.

- PTFE :

Elastomeric Bearings uses only virgin PTFE without regenerated or filler materials. The minimum thickness for bonded PTFE is 1.5 mm and varies in according with the bearings size and type. The minimum thickness of recessed PTFE is 4.5 mm and varies in according with the bearings size.

Specifications

- FRICTION OF THE BEARINGS :

The reaction of the bearing to the movement can be mathematically calculated by considering friction coefficient between stainless steel and PTFE to be 0,03. The exact friction coefficient between stainless steel and PTFE is determined in according to EN 1337-2.

- CORROSION PROTECTION :

Steel components exposed to the elements are protected against corrosion. It adapts the corrosion protection in accordance to the aggressiveness of the environment in which the bearings are to be installed and to each customer’s requirements. The standard corrosion protection according EN 1337-9 is as follows: - sandblasting SA2.5 grade - two components high thickness epoxy zinc paint: 250 µm The high resistant corrosion protection (metallization) is as follow: - sandblasting SA 2.5 grade - metal spraying to 85 µm with Zn/Al 85/15 - sealing: Epoxy sealer 20-25 µm - top coat: Polyurethane paint 100 µm

- DUST PROTECTION :

The dust protection around the sliding plate ensure the cleaning of the sliding surfaces to minimize the friction during sliding and guarantee the durability of the PTFE sliding material.