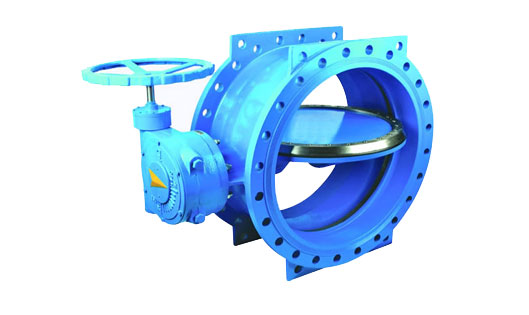

Upgrade to double eccentric butterfly valves for precise flow management. Trusted solutions for smooth operations and minimal downtime.

The newest generation of double eccentric butterfly valves with flow-optimized “Wave” design ensures minimized pressure losses and high energy-efficiency. Polygon connection of shaft and disc provides uninterrupted corrosion protection and optimal torque transmission at the same time. Use of slider crank gearbox allows safe operation of butterfly valves with minimized pressure surges.

Features

- Resilient seated , Face-to-face dimension

- Flange connection on both sides

- Low headloss, minimized flow restriction and high energy-efficiency

- Disc bearing in maintenance-free bushings, sealed by means of O-rings

- Polygon-connection of shaft and disc without additional security elements required, closed bearing-eyes for uninterrupted corrosion protection

- Corrosion- and wear-resistant overlay welded seat

- Optimum corrosion protection by epoxy powder coating according to GSK guidelines

- Standard actuation by robust and maintenance-free slider-crank gearbox, protection class IP 68, with integrated position indicator

- Modular actuation concept that allows use of hand wheel, electric actuator, extension spindle, hydraulic drop weight actuator, pneumatic actuator or chain wheel

- The double offset disc design ensures minimal seat wear and provides excellent throttling capabilities.

- Adjustable mechanical stopper provided on valve body ensures precise closing of the disc without over/under travel.

- Axial thrust bearing provided on valve ensures precise positioning of the disc and prevents unequal loading of the valve seat, it also enables installation of valve in any orientation of required.

Technical Specifications

| Feature | Value |

|---|---|

| Valve Type | Double offset disc double flanged Butterfly valve |

| Body Type | Double flanged |

| Seat Type | Fully replaceable fitted on the disc periphery |

| End Connection | Flanged |

| Size Range | 300 NB to 3000 NB |

| Operating temperature range | 0C to 180C (Depending on MOC) |

| Pressure Rating | PN 10/PN16/PN25/PN40/PN63 higher ratings on request |

| Seat Leakage | Tight shut off |

| Operation | Worm gear, Pneumatic & Electric actuators |

Conformity to Codes and Standards

- Complies with the requirements of European Pressure Equipment Directive PED 97 / 23 / EC

- Complies with the requirements of ATEX 94/9/EC

- General Design & Manufacturing: EN593/ API 609

- Face to Face Dimensions: Short pattern EN593 / API609 / ISO 5752 series-13 / AWWA C504.

- Top Flange Drilling: ISO 5211

- Valve Inspection & Testing: API 598 / EN593

- Flange Standard Conformity: BSEN 1092- PN6 / PN10 / PN16

- Flange Standard Conformity: WRAS Approved Coating & EPDM