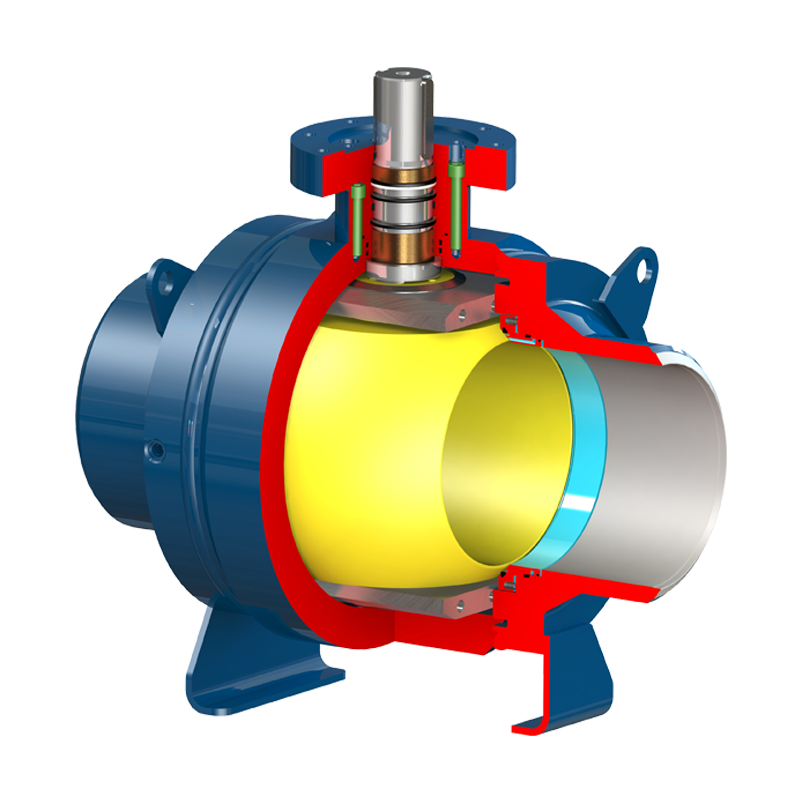

Our cryogenic ball valve is a critical piece of equipment that enables the smooth transportation of gas through pipeline systems. It is specially designed for quick opening and closing, with full bore or low-pressure drop for maximum efficiency.

At our company, we understand the importance of having reliable equipment in place, especially in industries where gases like oxygen, LNG, krypton, argon, and nitrogen are commonly used. That's why we've developed this cryogenic ball valve to meet the needs of various industries, including petrochemicals, aviation, medicine, and more.

Features & Benefits

Our cryogenic ball valve comes with an array of features that set it apart from other valves in the market. These features include:

Full Bore & Reduced Bore Design: Our cryogenic ball valve can be used with either a full bore or reduced bore design, depending on your specific needs.

Anti-Blowout Design: The valve is designed to prevent blowouts, even under high-pressure conditions.

Anti-Static Device: The anti-static device helps to reduce the risk of electrostatic discharge during use, which can be especially important in industries where gases are used.

Fire Safe Design: Our cryogenic ball valve has a fire-safe design that can withstand high temperatures and prevent the spread of flames.

Design & Specifications

Our cryogenic ball valve comes in a range of sizes, from DN 15 (1/2") to DN 150 (6"), and with pressure ratings ranging from PN 16 (class 150) to PN 160 (class 900). It can handle a wide temperature range of the transported medium, from -47°C to -196°C, making it suitable for the transportation of liquid nitrogen and LNG, among other industrial gases.

The design of our cryogenic ball valve is in compliance with EN 1626, EN 12567, EN 12300, and API 6D standards. We use extension lengths that are in accordance with BS 6364 and Shell MESC SPE 77/200 for your peace of mind.