Pressure-reducing valves directly work for slowing down the water pressure that flows into our home. Mainly on the main water line, they are installed just after the shut-off valve. On one side, the water coming from the main goes into the valve. When the water moves via the valve, it passes through the diaphragm and spring that creates resistance and reduces the pressure of the required level as the water leaves the valve from the other side.

The main feature of the pressure-reducing valves is that they’re set for regulating the flow of water into a specific pressure. It means that if there is a sudden increase in the municipal water pressure of the area, the diaphragm and spring in the valve will tighten and the users will still be having a continuous amount of pressure inside their home. Water is pumped at extremely high pressures by some of the municipal water mains and in some cases that can be more than 100 psi. Often, the pressure will be cranked up by Local water companies for delivering water to the places that are hard-to-reach like high elevation neighborhoods or high-rise buildings. Above 80 psi Water pressure can cause a significant amount of wear and tear to fixtures, pipes and appliances over time.

Every fixture, pipe, and appliance inside residential units are designed for withstanding a specific water pressure level, which conventionally lies between 60-80 psi. Faucets, showerheads, toilets, water heaters, pipe joints and appliances can all start to wear and gradually malfunction if they’re continuously under high pressures.

The spring-loaded Direct-acting spool pressure reducing valves are used in hydraulic systems for controlling the pressure of consumers. It is kept constant that the outlet pressure to the consumer, even as the inlet pressure and/or fluctuation of the load situation. Compared to the outlet pressure, the inlet pressure is bigger than the various ranges of pressure which enables an optimal system adjustment.

Comprising of the same essential components of direct-operated units along with an added pilot that can separate the diaphragm loading force (PL) and P2, Pilot operated regulators. The PL can be controlled with the connection to changes in P2 by doing this that indicates that the PL can be increased from P2, which makes the regulator much more responsive to the changing conditions. An external sense line is needed by the pilot that must be connected to the downstream piping. More accurate sensing of the true outlet pressure conditions when the sense point is moved away from the flow turbulence which is generated by the seat and plug is allowed by measuring the pressure farther downstream of the valves. Pressure-reducing valves have been designed to withstand even the most challenging of environments with ease. The valves are operated hydraulically, the diaphragm-controlled valve can reduce the higher pressure of upstream to lower constant downstream pressure without any regard for the fluctuating demand or the varied upstream force. These valves can efficiently maintain a steady downstream pressure needless of the flow. These valves incorporate a wide range of elements for assisting with optimal function. The body of the valve comes with an internal port which is a V-shaped throttling plug that offers a stable and accurate response for the pressure regulation and flows while also reducing the vibration and noise. The throttling V port plug can also allow the operation of the valve for closing to zero without hunting. The pilot regulator is often known as the valve’s brain. These determine the flow of the water towards and from the control chamber. This can also coincide with the needle valve for helping to regulate the flow and also maintains constant pressure.

For all your needs of Pressure Reducing Valves in the Middle East, you can get in touch with Dutco Tennant LLC. We are the most reliable supplier in the region having experience of more than four decades. We are committed to offering the information which you need for all of our technology, products and operating systems. For any other additional questions, you can get in touch with our team.

Pilot Operated - Ductile Iron

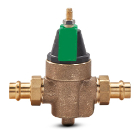

Direct Acting - Bronze