Rubber Duckbill Check Valve Solutions from Trusted Suppliers

Rubber Duckbill Check Valves are essential for maintaining reliable backflow prevention and fluid control in demanding environments. Supplied by Dutco Tennant LLC across the UAE and GCC, these duckbill check valves deliver consistent performance in municipal, industrial, and commercial systems. Designed for durability, the valves ensure safe operation in pipelines exposed to corrosive, marine, or high-pressure conditions, making them a dependable part of waste water solutionsand broader wastewater speciality valves applications.

Unlike traditional flap check valves, rubber duckbill non return valves operate without complex mechanical components, reducing maintenance needs while providing reliable sealing under reverse pressure. Their flexible rubber design adapts to fluctuating flows, offering quiet operation, corrosion resistance, and long-lasting reliability, which is why they are widely used in duckbill check valves wastewater systemswithin critical infrastructure.

Ideal for both new installations and retrofit projects, these valve duckbill solutionssupport critical infrastructure while ensuring energy-efficient and effective flow control in sewage, drainage, and industrial systems, aligning with advanced waste water solutionsand wastewater speciality valvescategories.

Key Advantages of Rubber Duckbill Check Valves

- Backflow Protection: Prevents reverse flow in low-pressure pipelines to safeguard infrastructure.

- Energy Efficient: Opens easily under minimal upstream pressure, reducing operational strain.

- Corrosion Resistant: Rubber construction withstands chemicals, saltwater, and aggressive fluids.

- Durable Design: Engineered for long-term performance in wastewater and drainage systems.

- Silent Operation: Flexible sleeve reduces noise compared to conventional rubber flap valves.

Flexible and Reliable Flow Control

- Operates without mechanical parts, minimizing risk of seizing or failure.

- Self-regulates flow, adapting to pressure fluctuations for consistent performance.

- Suitable for harsh environments such as industrial effluents and marine outfalls.

- Reduces maintenance costs compared to flap check valves and rubber flap valves.

- Compact design allows easy integration in constrained piping systems.

Types

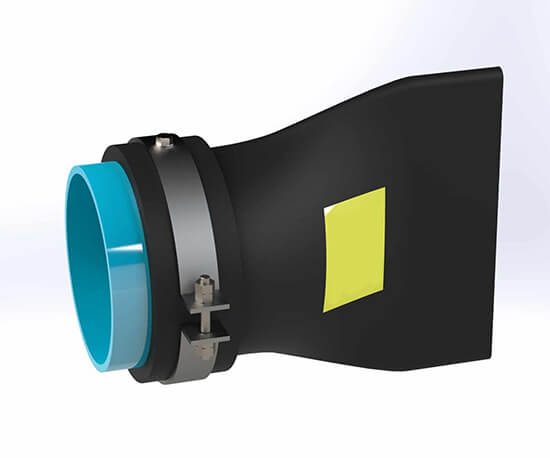

Rubber Duckbill Check Valve

A flexible valve that opens with forward flow and seals tightly to prevent backflow.

Ideal for wastewater, drainage, and industrial pipelines requiring non-clogging performance.

- Provides one-way flow in low-pressure systems

- Resists chemical and marine corrosion

- Minimizes maintenance and operational noise

Duckbill Non Return Valve

Designed for reliable backflow prevention in municipal and industrial systems.

It operates automatically based on differential pressure without external control.

- Ensures consistent reverse flow protection

- Works in sewage, stormwater, and effluent lines

- Supports long-term infrastructure applications

Valve Check Valve

A standard check valve solution for general water and wastewater applications.

Prevents backflow while maintaining energy-efficient flow management.

- Suitable for commercial, residential, and industrial pipelines

- Supports integration with existing piping networks

- Reduces operational and maintenance costs

Flex Check Valve

A soft, resilient valve that adapts to changing flow conditions in pipelines.

Provides quiet, reliable performance with minimal pressure drop.

- Reduces wear on system components

- Ideal for low- to medium-pressure applications

- Ensures long service life in harsh conditions

Wastewater Check Valve

Engineered for high-volume effluent and drainage systems in municipal and industrial setups.

Prevents contamination and protects infrastructure from backflow damage.

- Works effectively in stormwater, sewage, and industrial effluent lines

- Compact and corrosion-resistant design

- Supports critical municipal infrastructure

Standout Features & Benefits

Corrosion and Chemical Resistance

- Rubber construction withstands harsh chemicals, saltwater, and marine growth.

- Ensures reliable operation in demanding environments.

- Reduces downtime and long-term maintenance costs.

Quiet and Energy-Efficient Operation

- Flexible rubber sleeve opens with minimal upstream pressure.

- Silent operation improves facility comfort.

- Reduces energy consumption in fluid systems.

Reliable Backflow Prevention

- Automatically seals under reverse pressure to prevent contamination.

- Suitable for wastewater, irrigation, industrial, and residential applications.

- Minimizes risk of flooding or damage to critical pipelines.

Application Area

Municipal Drainage Systems

- Prevents backflow in urban sewage and stormwater networks.

- Protects infrastructure during high flow or tidal surges.

- Ensures safe, continuous operation.

Industrial and Wastewater Facilities

- Handles effluents and corrosive fluids reliably.

- Supports non-clogging flow management in processing lines.

- Reduces operational risks and maintenance costs.

Marine and Irrigation Systems

- Withstands saltwater exposure and tidal fluctuations.

- Ensures one-way flow in canals and outfall pipelines.

- Maintains consistent operation under varying water conditions.

Residential and Commercial Plumbing

- Protects homes and commercial facilities from sewage backflow.

- Offers durable and quiet operation in high-use environments.

- Provides dependable flow control for everyday water systems.

FAQ

Who supplies large rubber duckbill check valves in the UAE?

We at Dutco Tennant LLC supply reliable rubber duckbill check valves designed for harsh drainage, sewage and industrial environments across the UAE and GCC.

What is the lifespan of a duckbill valve?

They have no mechanical parts and resist corrosion, rubber check valves generally deliver long service life even in demanding wastewater conditions.

How often should duckbill valves be replaced?

Replacement is rare. Since flex check valves are self-operating and corrosion-resistant, they only need changing when the rubber loses shape or no longer seals.

What material is used for duck bill valve construction?

Duckbill non return valves are made from durable elastomeric rubber, giving them flexibility, corrosion resistance and reliable sealing under varying pressures.

How do you know if a check valve non return valve needs replacement?

If you notice backflow, leakage, or a deformed rubber sleeve, the valve duckbill is no longer sealing properly and should be replaced.

Why are duckbill valves better than flap check valves?

Duckbill check valves perform better because they have no metal parts to rust or jam. They seal automatically, stay quiet and work well in sewage or sludge.

How does a rubber flap valve prevent backflow?

The flexible sleeve opens with forward flow and closes when pressure reverses. This simple motion creates a tight seal that stops backflow instantly.

Do flex check valves need maintenance?

They are virtually maintenance free. With no hinges or moving parts, the rubber design operates quietly and stays reliable even in corrosive environments.