.jpg)

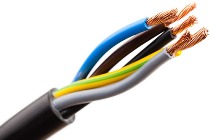

The harshest environmental conditions, contact with flames, and surface abrasion can be withstood by conductor cables. They can be used for versatile applications and are suitable for use in various applications which range from small pieces of electronics to a large amount of factory automation. These cables are physically rugged and they can very easily withstand the most demanding applications. The jackets and conductors have various insulation compounds like PVC, PTFE, Kynar, Polyethylene, Silicone, Hypalon, and Polypropylene. These are multi-conductor cables that are available in various shielding or overall shielding. In cases when each of the wires comes with some types of shield, the individual shielding can be identified. The entire shielding is required when the shield has been applied around all the wires present inside a group. The shields can be found in braid, foil, or both. The braid/foil or foil shield is used to ensure signal integrity and electrical performance. No matter if you are in need of powering up a small device or the powerlines that are offering electricity to an entire city, a conductor is a material that makes way for the free flow of electric current. In the invention of an electrical circuit system, the conductor is referred to mostly as the piece that can transfer the electrical current from the source towards the load. The multi-conductor cable is available in a wide range of configurations and features annealed stranded tinned copper wire, all of which are compliant with UL, RoHS, and CSA. In several UL styles and color-coded PVC, and also comes with a chrome gray PVC outer jacket, insulations are available which have a varied temperature range. These cables are available in several thickness of jacket which depends on the count of the conductor. With polyester aluminum foil shields which have a stranded copper drain wire, annealed stranded tinned copper wire, and polyethylene color-coded insulation, this cable has been made. They are having an unmatched ability to ensure uptime, and these conductor cables have been specifically made for rugged industrial jobs for various decades. They can easily match up with the technical requirements of several system types with proven best-in-class reliability and performance.

Features

- Ratings, approvals, and performance testing for ensuring longevity and regulatory compliance

- Highly reliable and unmatched quality

- Has a robust design which can meet or exceed the UL standards

- Designed with options and features which can allow designers to match cable selection with environmental conditions within a diverse array of applications

- Wide range of shielding options, AWG sizes, pair counts, and conductor types