FILTER PRESSES

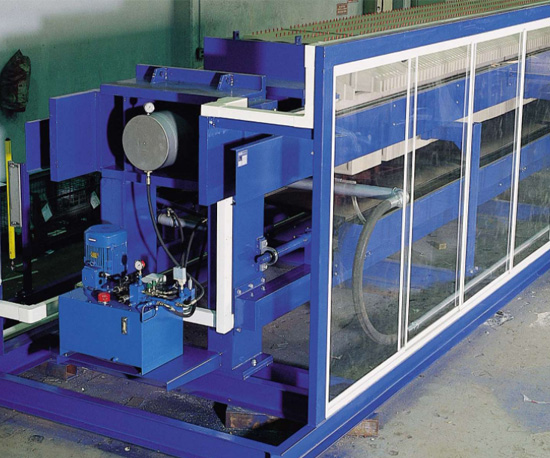

A filter press is a type of mechanical equipment which achieves solid-liquid separation of slurry using pressure filtration with the help of filter plates and clothes. Filter presses are the parts of batch operations and commonly used for sludge dewatering in municipal and industrial wastewater treatment plants due to their economical and easy-to-operate design.

Filter presses are generally consist of metal components, plates and filter clothes. The main purpose of metal components is to protect the filtration unit from pressure applied during operation. Filtration unit is the part of equipment which separate solid and liquid in filter presses. This unit is composed of the plates having the same sizes. Filter clothes are worn on each plate to obtain a filtration unit. The function of filter clothes is to allow the water present in slurry to pass through the pores of the clothes and collect sludge cake on the cloth. Dewatering ratio of filter press is more than decanter’s and belt press’ which are the equipment used for the same purpose.

Main working logic is based on that the slurry to be dewatered passes through the plates inside the filter press and the volume of it is reduced by filtering the water. The water filtered passes through the filter clothes and leaves the sludge cake behind. Thereafter, the sludge cake is discharged from the system. Sludge cake discharge system can be designed as automatic or manual according to the customers’ requirements.

Sismat Uluslararası offers three types of filter presses:

Chamber type filter presses (FPC) are the most common type of filter presses due to the reliable and flexible design. They have a series of filter plates with a cavity on the plates placed collaterally to obtain an empty chamber.

Mixed type filter presses (FPX) are designed by combining chamber and membrane types of filter presses to obtain the cake thickness desired. It is the oldest design and preferred rarely.

Sismat Uluslararası Filter Presses are mainly made up of filter plates, filter clothes, filtrate tray, drip tray, cloth washing system and drive unit.

FEATURES AND BENEFITS OF SISMAT ULUSLARARASI FILTER PRESSES

• Commonly used equipment due to robust and durable construction

• Reliable and trouble-free operation

• Efficient and economical solution for sludge dewatering

• Fine filtration provided under high pressure

• Food and beverage industry,

• Chemical industry,

• Agricultural industry,

• Metal working and surface

finishing industry, etc.

• Plastics recycling plants

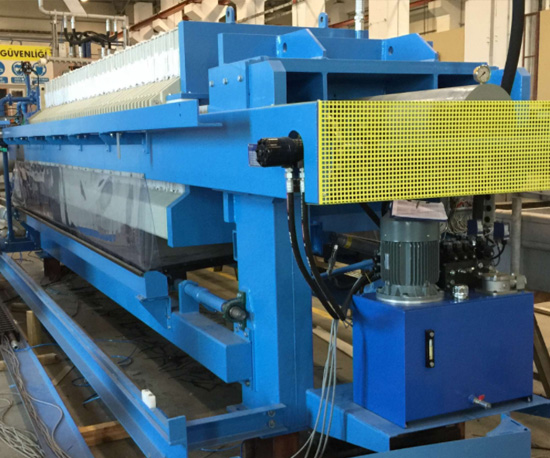

A filter press is a type of mechanical equipment which achieves solid-liquid separation of slurry using pressure filtration with the help of filter plates and clothes. Filter presses are the parts of batch operations and commonly used for sludge dewatering in municipal and industrial wastewater treatment plants due to their economical and easy-to-operate design.

Filter presses are generally consist of metal components, plates and filter clothes. The main purpose of metal components is to protect the filtration unit from pressure applied during operation. Filtration unit is the part of equipment which separate solid and liquid in filter presses. This unit is composed of the plates having the same sizes. Filter clothes are worn on each plate to obtain a filtration unit. The function of filter clothes is to allow the water present in slurry to pass through the pores of the clothes and collect sludge cake on the cloth. Dewatering ratio of filter press is more than decanter’s and belt press’ which are the equipment used for the same purpose.

Main working logic is based on that the slurry to be dewatered passes through the plates inside the filter press and the volume of it is reduced by filtering the water. The water filtered passes through the filter clothes and leaves the sludge cake behind. Thereafter, the sludge cake is discharged from the system. Sludge cake discharge system can be designed as automatic or manual according to the customers’ requirements.

Sismat Uluslararası offers three types of filter presses:

Chamber type filter presses (FPC) are the most common type of filter presses due to the reliable and flexible design. They have a series of filter plates with a cavity on the plates placed collaterally to obtain an empty chamber.

Mixed type filter presses (FPX) are designed by combining chamber and membrane types of filter presses to obtain the cake thickness desired. It is the oldest design and preferred rarely.

Sismat Uluslararası Filter Presses are mainly made up of filter plates, filter clothes, filtrate tray, drip tray, cloth washing system and drive unit.

FEATURES AND BENEFITS OF SISMAT ULUSLARARASI FILTER PRESSES

• Commonly used equipment due to robust and durable construction

• Reliable and trouble-free operation

• Efficient and economical solution for sludge dewatering

• Fine filtration provided under high pressure

• Food and beverage industry,

• Chemical industry,

• Agricultural industry,

• Metal working and surface

finishing industry, etc.

• Plastics recycling plants

Other Details

- High solid matter content in sludge cake

- Sustainable operation ability

- Automatic washing system for filter cloths

- Low energy consumed

- Low operation and maintenance cost