BELT PRESSES

effective solutions for dewatering

Excess amount of water is still present in sludge thickened and it needs to be removed to have more stable and easy‑to-handle sludge in less volume and to make it less expensive for transporting.

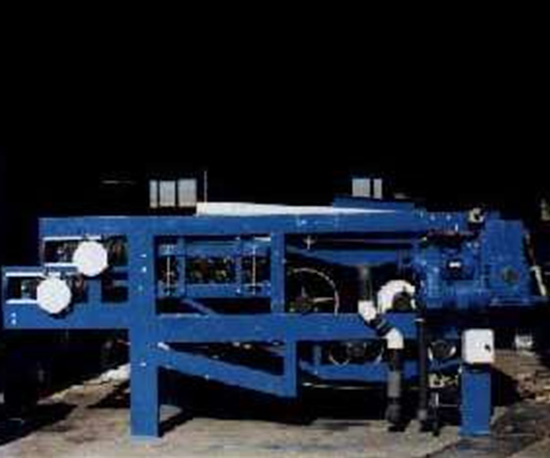

Belt presses are the equipment working continuously and used for dewatering of sludge from municipal and industrial wastewater treatment plants as well as water treatment plants in medium and large sizes. They are cost-effective, efficient solutions for dealing with sludge flows in large scales. Main working logic is based on filtering the water by pressing the sludge between belts and drums.

One of the most important points to obtain maximum efficiency from belt presses is the selection of best-fit equipment. Sismat Uluslararası offers the best solution according to the customers’ demands. The capacity and performance of belt presses can be defined with regard to the criteria below:

• Belt width

• Pressure applied

• Number of drums

• Pre-dewatering section height

Sismat Uluslararası Belt Presses are mainly made up of pre-dewatering part, cake thickness adjustment part (in MBP and HBP series only), low-pressure dewatering part, high-pressure dewatering part, belt washing part, and cake transportation part.

• Pre-dewatering part is where the flocculated sludge leaves a considerable portion of its water content by gravity.

• Cake thickness adjustment part (in MBP and HBP series only) is where the cake thickness is adjusted prior to pressing to allow it to spread homogeneously in the pressure zone without overflowing between drums.

• Low-pressure dewatering part is where a low level pressure is applied to sludge by large diameter, perforated drums for a long period.

• High-pressure dewatering part is where the drum diameters decrease gradually as the discharge section is approached, thus applying higher pressure for shorter periods to the sludge and reducing its water content.

• Belt washing part is where an automatic selfcleaning process that increases efficiency, takes place by using the nozzles. The cleaning of automatic self-cleaning nozzles can be started by an operator at determined time intervals, or by additional time control automation.

• Cake transportation part is where the cake can be transported by using containers or a conveyor system.

FEATURES AND BENEFITS OF SISMAT ULUSLARARASI BELT PRESSES

• Compact and reliable design

• Robust and durable construction which requires low maintenance

• Continuous dewatering process

• High solids rate obtained

• Trouble-free and noiseless operation

• Easy-to-operate and-maintain

• Long lifetime

• Adjustable belt speed provided

• Low label requirement

• Low energy consumption & High efficient system

Excess amount of water is still present in sludge thickened and it needs to be removed to have more stable and easy‑to-handle sludge in less volume and to make it less expensive for transporting.

Belt presses are the equipment working continuously and used for dewatering of sludge from municipal and industrial wastewater treatment plants as well as water treatment plants in medium and large sizes. They are cost-effective, efficient solutions for dealing with sludge flows in large scales. Main working logic is based on filtering the water by pressing the sludge between belts and drums.

One of the most important points to obtain maximum efficiency from belt presses is the selection of best-fit equipment. Sismat Uluslararası offers the best solution according to the customers’ demands. The capacity and performance of belt presses can be defined with regard to the criteria below:

• Belt width

• Pressure applied

• Number of drums

• Pre-dewatering section height

Sismat Uluslararası Belt Presses are mainly made up of pre-dewatering part, cake thickness adjustment part (in MBP and HBP series only), low-pressure dewatering part, high-pressure dewatering part, belt washing part, and cake transportation part.

• Pre-dewatering part is where the flocculated sludge leaves a considerable portion of its water content by gravity.

• Cake thickness adjustment part (in MBP and HBP series only) is where the cake thickness is adjusted prior to pressing to allow it to spread homogeneously in the pressure zone without overflowing between drums.

• Low-pressure dewatering part is where a low level pressure is applied to sludge by large diameter, perforated drums for a long period.

• High-pressure dewatering part is where the drum diameters decrease gradually as the discharge section is approached, thus applying higher pressure for shorter periods to the sludge and reducing its water content.

• Belt washing part is where an automatic selfcleaning process that increases efficiency, takes place by using the nozzles. The cleaning of automatic self-cleaning nozzles can be started by an operator at determined time intervals, or by additional time control automation.

• Cake transportation part is where the cake can be transported by using containers or a conveyor system.

FEATURES AND BENEFITS OF SISMAT ULUSLARARASI BELT PRESSES

• Compact and reliable design

• Robust and durable construction which requires low maintenance

• Continuous dewatering process

• High solids rate obtained

• Trouble-free and noiseless operation

• Easy-to-operate and-maintain

• Long lifetime

• Adjustable belt speed provided

• Low label requirement

• Low energy consumption & High efficient system