Downstream Defender® is an advanced hydrodynamic vortex separator that reliably captures and retains sediments, oil, trash and floatables from surface water runoff.

A compact, low-maintenance stormwater treatment BMP, the Downstream Defender® enables engineers to deliver effective pollutant removal at a single point in the drainage system.

A compact, low-maintenance stormwater treatment BMP, the Downstream Defender® enables engineers to deliver effective pollutant removal at a single point in the drainage system.

Overview

The Downstream Defender® is an advanced hydrodynamic vortex separator that provides impressive and reliable removal of fine and coarse particles, hydrocarbons and floatable debris from surface water runoff, delivering high levels of stormwater treatment over a wide range of flow rates.

Available in a range of sizes, it can function as either pretreatment or as a stand-alone device, providing engineers and contractors with a flexible, cost-effective stormwater management option.

Targeted Pollutants:

•Fine and coarse particles / total suspended solids (TSS)

•Floatable trash and debris - now available with 5mm screen to meet 100% trash capture TMDL

•Liquid- and sediment-bound oils and hydrocarbons

•Sediment-bound heavy metals

•Sediment-bound nutrients

Available in a range of sizes, it can function as either pretreatment or as a stand-alone device, providing engineers and contractors with a flexible, cost-effective stormwater management option.

Targeted Pollutants:

•Fine and coarse particles / total suspended solids (TSS)

•Floatable trash and debris - now available with 5mm screen to meet 100% trash capture TMDL

•Liquid- and sediment-bound oils and hydrocarbons

•Sediment-bound heavy metals

•Sediment-bound nutrients

Benefits

Save space and money

Downstream Defender® can treat high peak flows in as little as half of the footprint of other structural BMP systems. A smaller footprint means an easier install that's less expensive and requires less work. The Downstream Defender® is proven to prevent washout of captured pollutants. Carefully designed internal components isolate the pollution storage areas, ensuring that what is captured is retained, even during high flows.

Adaptable

The Downstream Defender® can accommodate a change in outlet pipe direction to suit site-specific requirements.

Cut headloss

Low headloss means more site flexibility and provides engineers with design options for shallower sites.

Downstream Defender® can treat high peak flows in as little as half of the footprint of other structural BMP systems. A smaller footprint means an easier install that's less expensive and requires less work. The Downstream Defender® is proven to prevent washout of captured pollutants. Carefully designed internal components isolate the pollution storage areas, ensuring that what is captured is retained, even during high flows.

Adaptable

The Downstream Defender® can accommodate a change in outlet pipe direction to suit site-specific requirements.

Cut headloss

Low headloss means more site flexibility and provides engineers with design options for shallower sites.

How it works

How it works

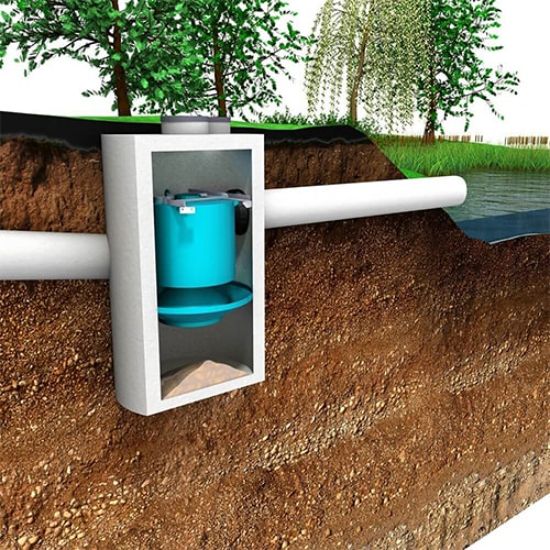

The Downstream Defender® stormwater treatment system is designed to enhance vortex separation by minimizing turbulence and headloss, increasing efficiency, and preventing washout of stored pollutants.

1. Contaminated stormwater is introduced tangentially into the side of the vessel, generating a rotating flow that spirals around the outside of the dip plate.

2. Oils, trash and floatable debris rise to the water surface and are trapped in the oil and floatables storage volume.

3. As flow continues to spiral down around the dip plate cylinder, low energy vortex motion directs sediment inward along the benching skirt and into the protected sediment storage zone.

4. The benching skirt and center cone redirect the rotating flow up and inward between the center shaft and dip plate cylinder away from the stored sediment.

5. The outlet pipe discharges treated effluent from within the dip plate cylinder ensuring the longest possible residence time.

The Downstream Defender® stormwater treatment system is designed to enhance vortex separation by minimizing turbulence and headloss, increasing efficiency, and preventing washout of stored pollutants.

1. Contaminated stormwater is introduced tangentially into the side of the vessel, generating a rotating flow that spirals around the outside of the dip plate.

2. Oils, trash and floatable debris rise to the water surface and are trapped in the oil and floatables storage volume.

3. As flow continues to spiral down around the dip plate cylinder, low energy vortex motion directs sediment inward along the benching skirt and into the protected sediment storage zone.

4. The benching skirt and center cone redirect the rotating flow up and inward between the center shaft and dip plate cylinder away from the stored sediment.

5. The outlet pipe discharges treated effluent from within the dip plate cylinder ensuring the longest possible residence time.

Features

- Single manhole design

- Variable inlet/outlet angle configurations (not just 180 degree orientation)

- Internal bypass for inline installation (where applicable)

- All units can be installed into a standard precast manhole

- 4’ units can be factory fabricated in HP manholes for quick delivery with a light, easy to install structure

- In-stock components for quick delivery

- No elevation loss between the inlet and outlet

- Surface inspection and maintenance with no confined space entry