Pressure Relief or Pressure Sustaining Valve regulates upstream pressures by relieving the surplus pressure downstream or via a return line. They work in a similar way like a relief valve but are more accurate, responsive and only open far enough to relieve sufficient pressure for maintaining the desired pressure upstream. The pressure to be maintained is known as the set pressure and is easily adjusted by turning the adjusting bolt, thus compressing the spring. Pressure Sustaining valves serve the purpose of maintaining pressure in a fluid circuit by opening only as much as required to maintain the required pressure on their inlet port. The pressure sustaining valve has the same meaning as of the back pressure valve or back pressure regulator.

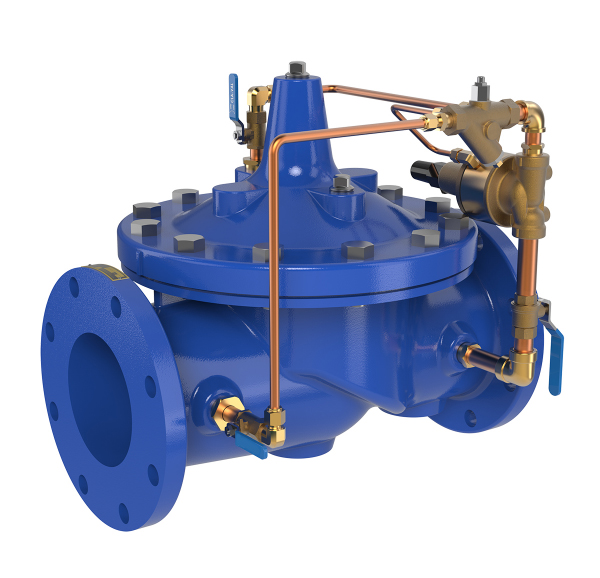

The model of Pressure Sustaining Valve which we supply is a hydraulically operated, pilot-controlled, modulating valve designed to maintain constant upstream pressure within close limits. This valve can be used for pressure relief, pressure sustaining, back pressure, or unloading functions in a by-pass system. While in operation, the valve is actuated by line pressure through a pilot control system, opening fast to maintain steady line pressure but closing gradually to prevent surges. Operation is completely automatic and pressure settings may be easily changed. When a check feature is added into it and a pressure reversal occurs, the downstream pressure is admitted into the main valve cover chamber, closing the valve to prevent the return flow.

This fast opening, slow-closing relief valve provides system protection against high-pressure surges on pump start-up and pump shut down by dissipating the excess pressure to a safe location. When it is installed in a line between an upper zone and a lower area of heavy demand, the valve acts to maintain desired upstream pressure for preventing “robbing” of the upper zone. Water in excess of pressure setting is allowed to flow to areas of heavy demand, control is smooth and pressure regulation is positive.

Typical Applications

- Isolation valve

- Booster pump

- Pump suction Line

Technical Specifications

- Strainer: Brass

- Diaphragm: EPDM

- Needle Valve: Brass

- Stem: Stainless Steel 316

- Coating: Non-Toxic Epoxy

- Body: Ductile Iron ASTM A 536

- Pressure rating : PN10,PN16,PN25

- Bonnet: Ductile Iron ASTM A 536

- Available Sizes: 50mm – 1000mm

- Valve body Type: Globe Type/ Angle Type

- Pressure Relief Pilot: Brass/Stainless Steel

- Tubing & Fittings: Copper, Brass, Stainless Steel

Features

- Quick opening relief.

- Easily adjustable pressure setting.

- Limits system pressure by relieving excess flow.

- Ensures minimum upstream pressure for critical use.

- Easily adjustable pressure setting Closes if inlet pressure drops below set-point.

- The 50 Series Pressure Relief Valve is designed to maintain constant upstream pressure within close limits. In operation, the valve is actuated by line pressure through a pilot control system, opening fast to maintain steady line pressure but closing gradually to prevent surges. In addition to surge relief, this valve can be used for pressure relief, pressure sustaining, back pressure or unloading functions in a by-pass system.