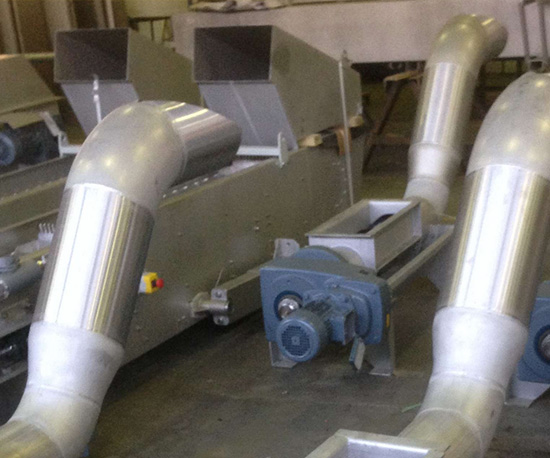

Screenings removed by sieves or fine screens contain water and their volume is swollen. Sismat Uluslararası Screening Presses are most suitable units for the solution of this problem reducing the weight and volume of your screenings. Screenings Washing and Dewatering Press uses a conveyor screw to process raw wastewater screenings – conveying, washing out fecal matter and dewatering screenings to reduce discharged volume and liquid content. Screened particles hold high amounts of water. Our units can dewater screenings up to 70 % dryness by dewatering the screened materials. Reduction in weight and volume means ease of handling and decreasing transportation costs. Sismat Uluslararası Screening Presses are furnished with compacting screws of high wearing resistant, heavy duty bearings and reducers. Due to the simple and robust design, the maintenance cost of the units is very low. Depending on the type and size of the particles present in the wastewater, the dewatering part of the compactor can be of perforated steel or V-weir meshes type. Screening presses can be operated either by the signal which will be sent from the screen control panel or by means of a sensor which will be installed in loading box. Overload protection can be maintained via mechanical torque limiter. They can also be manufactured with washing system that allows reducing organic matter in the waste. Waste water from washing or compacting process can be discharged to screen channel. The washed and compacted screenings are finally transported through the conical discharge pipe into a skip. Sismat Uluslararası Screening Presses are mainly made up of frame, screw, screen, hopper, drive unit and discharge pipe.

FEATURES AND BENEFITS OF SISMAT ULUSLARARASI SCREENING PRESS

• Simple and robust design

• Reduction of water amount by 70%

• Reduction of waste volume by 40%

• Various capacities and installation types

• Low noise level

• Easy-to-install for all types of screens

• Low operating and maintenance costs

• Low energy consumption