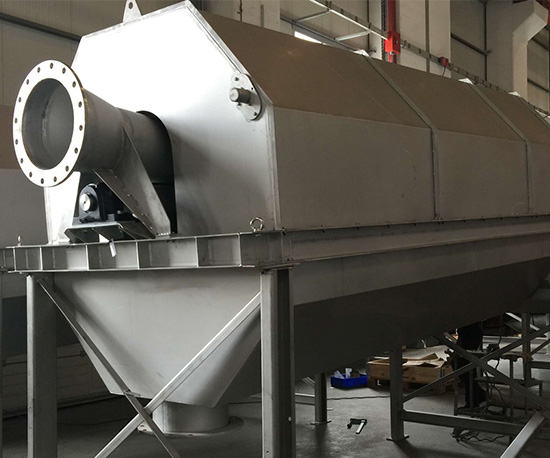

A rotating drum is employed by the Internally Fed Drum Screens for Wastewater Treatment for providing effective fine screening for a varied range of materials with a simple and reliable design. A cylindrical screen is employed by the construction with perforated metal, wedge wire, or filter cloth along with a weir system. As the material is fed into the inlet of the unit it is distributed along the internal screen surfaces. The weir moves the solids along the screen length as the drum rotates. Through the bottom of the units, the liquids are discharged. The solids are conveyed to the unit discharge flange.

The internally fed rotary drum screens are composed of a tank and a spiral connected to a drum for screening transportation. With a perforated plate, the drum screen is made and the selection of the perforated holes profile diameter can be done according to the requirements of the user. With nylon wheels, the drum screen is supported and it is operated with the help of a gearbox. Through a nozzle that is placed in the front of the machine, the filter is fed. With the help of a diffuser, the water is spread on a large area of the rotating screen that separates the water from the organic particles contained in it. Through a washing system that comprises a tube with spray nozzles for pressurized water, the filter is cleaned. During the operation of the equipment, the water is conveyed at the outlet placed in the front of the machine while the screening is transported by the spiral towards the screening outlet in the back of the machine. For contributing towards the dewatering of screenings, the screen inclination is made and the screen is also equipped with a bypass pipe for avoiding overflows with a predisposition for an overflow sensor. The Internally Fed Drum Screens for Wastewater Treatment are the equipment that is preferred for separating the settleable solids from liquid and is generally used in municipal and industrial wastewater treatment plants. Because of the fact that they make the load of wastewater reduced and protect the following equipment, at the end process, less amount of waste sludge can be obtained. These screen types used the internal surface of the drum. As wedge-wire or perforated, the screening media can be manufactured. The screen surface is cleaned with an automatic washing mechanism equipped with special nozzles. For preventing odour problems, internally fed rotary drum screens can be completely covered for being able to prevent odour problem and protected by torque limiter system in case of overload conditions. We supply Internally Fed Drum Screens for Wastewater Treatment which are mainly composed of frame, scrapper plaque, screen drum and drive unit.

Features and Benefits

- Highly efficient waste recovery

- Robust proven design

- Has automatic cleaning mechanism

- Easy to install and operate

- Is the most economical option

- Very easily maintainable and serviceable

- Consumes very low energy

- Minimal investment and operation cost

Other Details

- Internally fed rotary drum screens are the equipment which are preferred for separation of settleable solids from liquid and generally used in municipal and industrial wastewater treatment plants. Due to the fact that they make the load of wastewater reduced and protect the following equipment, less amount of waste sludge can be obtained at the end of process. This type of screen utilizes the internal surface of the drum. Screening media can be manufactured as wedge-wire or perforated. Screen surface is cleaned with an automatic washing mechanism equipped with special nozzles. Internally Fed Rotary Drum Screens can be fully covered to be able to prevent odour problem and protected by torque limiter system in case of overload conditions.

- Robust proven design

- Waste recovery with high efficiency

- Automatic cleaning mechanism

- Economical option for fine screening

- Simple installation and start-up

- Easy maintenance and service

- Low investment and operation cost

- Low energy consumption