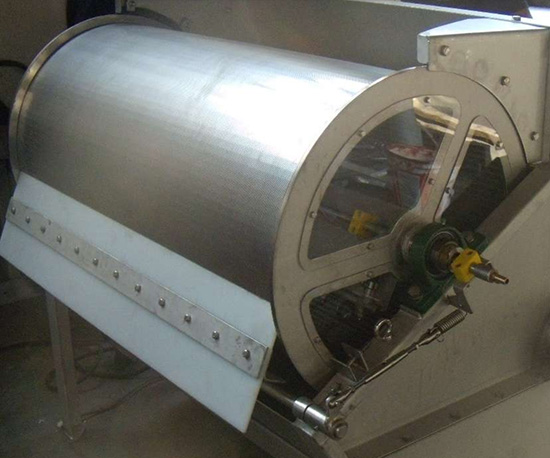

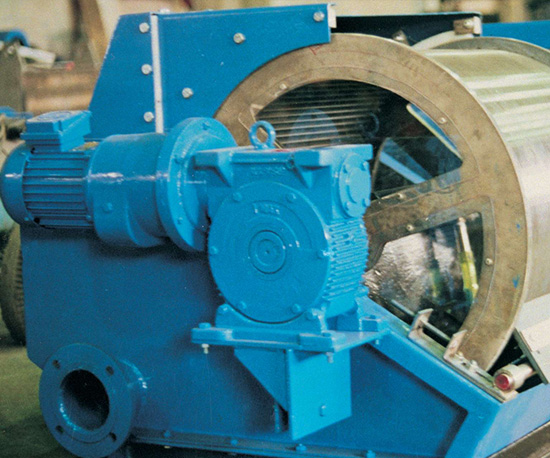

The Externally Fed Rotary Drum Screens is a highly reliable self-cleaning wedge wire screen that is recommended for use in both municipal and wastewater operations as well as several industrial screen applications. This screening technology can perform very well in wastewater with heavy oil or grease loadings as well as scum applications that can blind other screen types. Within the municipal wastewater, screens are used for fine screening primary sewage influent at the headworks and also as screening of clarifier scum. The other industrial screen applications which commonly use the externally fed drum screens include poultry and meat processing, pulp, and paper debarking, seafood offal effluent, the drum screen is constructed slotted stainless wedge wire, cylindrical drums which rotate on two pillow block bearings. The screen mainly has a lot of opening ranging. the feature-complete overflow protection from flows or blinding.

In wastewater treatment plants, it is highly renowned as a fine screen required for pretreatment, it is also the preferred choice of the industry for scum screening. Users of the industry like food processors, meat processors, tanneries, petrochemical plants, textile mills, and recyclers who rely on this for wastewater treatment and product recovery. The externally fed rotary screens are considered to be fine screens that are mounted to the pipeline that is operated on the basis that the floating solid substances which are trapped in the wastewater are kept outside the screen. They are drum screens which are used for separating the wastes from domestic treatment plants but also several kinds of process wastes from industrial wastewater treatment plants. There are mainly two variants of screens which are used in externally fed rotary drum screens like perforated plates and wedge wires. A high waste capture rate is provided by the perforated plates having material sizes that are bigger than the perforation size. On the other hand, wedge wires minimize the risk of clogging and maximizes the permeability ratio with the v-shaped profile. Through a distributor onto the external surface of the drum screen, the wastewater is conveyed. The side sealing is made up of nylon sliding blocks. On the external surface of the drum screen, the solids are retained and subsequently discharged. By the means of a brass plate, the drum is cleaned. After passage through the inside of the drum screen, clean water is collected on the bottom of the tank and is then discharged via a nozzle. By coupling connection to a gear reducer mounted at the end of the drum, rotation of the filter occurs. A cleaning system is installed at the opposite end of the cleaning system. With a pipe equipped with a high-pressure nozzle, the system is composed of which periodically cleans the filtering drum. The system needs to be connected to the water mains.

Features and Benefits

- Automatic operation with high efficiency

- Due to a completely covered system, no odor, and waster splash problem

- Low energy consumption

- Minimum maintenance and easy clean-up

- Compact design

- Wide range of capacity

Other Details

- Externally fed rotary screen systems are considerably fine screens mounted to the pipeline, which are operated on the basis that the floating solid substances contained in the wastewater are kept outside the screen used for the separation of the wastes from domestic treatment plants, but also different kinds of process wastes from industrial wastewater treatment plants. There are two types of screen used in externally fed rotary drum screens as "perforated plates" and "wedge wires". Perforated plants provide a high capture rate of materials bigger than the performance size. On the other hand, wedge wires minimizes risk of clogging and maximizes permeability ratio with the V-shaped profile.

- No odor and water splash problem due to completely covered system

- Automatic operation in high efficiency

- Low energy consumption

- Easy clean-up and minimum maintenance

- Wide range of capacity

- Compact design