SWC5LD Seawater Membranes UAE

Dutco Tennant LLC offers high-quality Hydranautics seawater RO membranes to meet the growing water needs in the UAE and GCC. These sea water RO membranes UAE are designed for efficient seawater desalination and industrial water treatment, providing reliable performance, consistent water flow, and high salt rejection in RO systems.

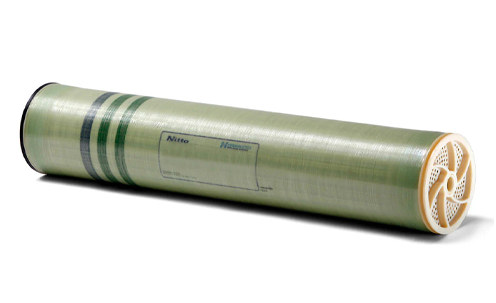

The Hydranautics SWC5LD membrane is engineered for large-scale desalination plants and industrial RO operations. With spiral-wound composite polyamide construction, these membranes deliver durability, low fouling, and energy-efficient operation, ensuring long-term reliability for municipal, commercial, and industrial water systems.

SWC5 RO membranes UAE maintain stable water quality while minimizing maintenance requirements. The LD models reduce fouling and maintain low feed pressure, while MAX models provide large active areas for boron removal and enhanced TDS reduction. These features make the membranes ideal for industrial RO membranes, reverse osmosis water membranes, and membrane water treatment applications.

Dutco Tennant ensures every Hydranautics SWC5LD membrane meets strict quality standards, providing reliable performance in seawater reverse osmosis membranes, SWRO systems, and water purification membranes for residential, industrial, and municipal applications.

Hydranautics SWC5LD Membranes

The SWC5LD membrane is part of the SWC5 series, engineered for high salt rejection and efficient water flow. It is suitable for large-scale industrial and municipal RO systems.

- LD Models: Reduce fouling, maintain low feed pressure, and increase intervals between cleanings

- MAX Models: Offer up to 440 ft² active area for effective TDS and boron removal

- Made from spiral-wound composite polyamide for durability and low fouling

- Compatible with Hydranautics RO membranes, SWRO membranes, and industrial RO setups

Performance and Design Highlights

Hydranautics SWC5LD membranes are engineered for reliable seawater RO operation with consistent water quality and high salt rejection. Their spiral-wound composite polyamide construction ensures durability, low fouling, and energy-efficient performance across industrial, municipal, and commercial RO systems.

- High salt rejection in RO ensures safe and clean water production

- Optimized flow design reduces energy consumption and operational costs

- Low-fouling structure minimizes maintenance and extends membrane life

- Compatible with SWRO membranes, reverse osmosis water membranes, and industrial RO membrane systems

- Designed to maintain performance in high-salinity and warm seawater conditions

Types

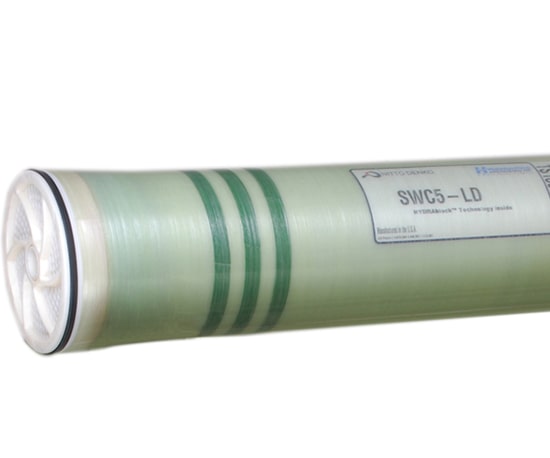

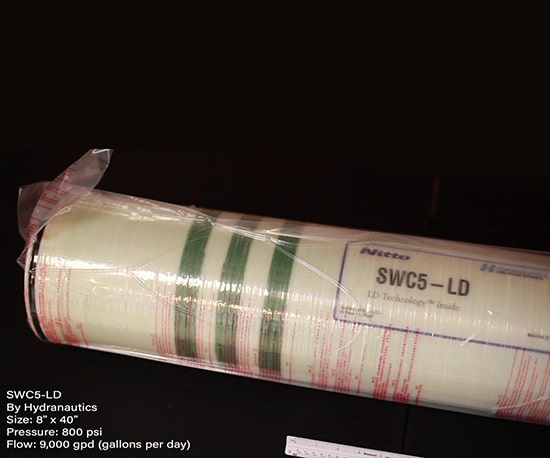

SWC5LD Membrane

Designed for high-performance seawater RO desalination and long-lasting industrial operation.

- Reduces fouling and maintenance requirements

- Maintains consistent water quality and high salt rejection

- Suitable for municipal and industrial reverse osmosis water membranes

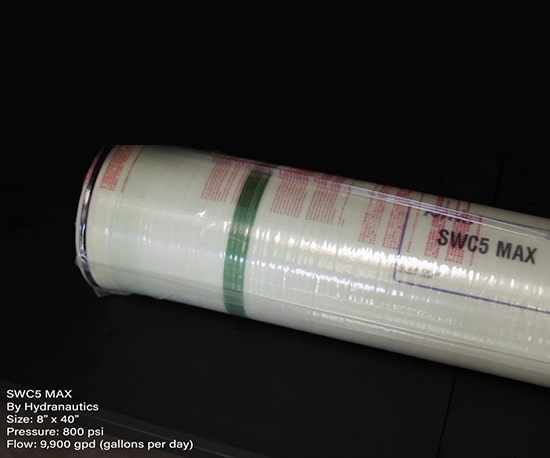

SWC5 MAX Membrane

Engineered for higher flow rates and boron removal in seawater RO systems.

- Provides 440 ft² active area for optimal performance

- Maintains stable water quality under high TDS conditions

- Ideal for large-scale seawater desalination projects

SWC5 Standard Membrane

Optimized for conventional industrial RO systems.

- Durable spiral-wound design for long life

- Maintains high salt rejection and stable water flow

- Compatible with industrial RO membranes and membrane water treatment setups

SWC5 LD Compact Membrane

Designed for modular or smaller industrial RO systems.

- Maintains low fouling and optimized feed pressure

- Energy-efficient operation with consistent performance

- Suitable for commercial, municipal, and industrial RO systems

Standout Features & Benefits

Reliable Performance for Seawater RO Systems

- 99.8% salt rejection ensures clean water production

- High water flow with effective TDS and boron removal

- Durable spiral-wound Hydranautics seawater RO membranes construction

- Low-fouling design reduces maintenance and downtime

- Energy-efficient operation minimizes operational costs

- Compatible with industrial RO membranes, reverse osmosis water membranes, and SWRO systems

Application Area

Where Hydranautics SWC5LD Membranes Are Used

- Seawater desalination plants in UAE and GCC

- Industrial RO membrane systems for commercial and industrial operations

- Large-scale membrane water treatment projects

- SWRO plants and reverse osmosis water membrane installations

- Municipal and industrial sea water RO membranes UAE for consistent water quality

FAQ

What is the primary use of SWC5LD membranes?

SWC5LD membranes are used for seawater RO desalination and industrial water treatment, ensuring reliable performance, consistent water flow, and high salt rejection for municipal and commercial systems.

How do LD models reduce maintenance?

LD models minimize fouling and maintain low feed pressure, extending intervals between cleanings and supporting energy-efficient operation in industrial and municipal RO systems.

Can SWC5 MAX membranes remove boron effectively?

Yes, SWC5 MAX membranes with 440 ft² active area provide efficient boron removal and consistent water quality, even under high TDS and warm seawater conditions.

Are these membranes energy-efficient?

Yes, SWC5LD membranes feature optimized flow design and low-fouling construction, reducing power consumption and ensuring energy-efficient operation for SWRO and desalination plants.

How long do SWC5LD membranes last?

With proper pre-treatment and monitoring, SWC5LD membranes maintain high salt rejection, consistent water flow, and long-term performance for multiple years.

Are SWC5 membranes suitable for UAE conditions?

Yes, SWC5LD membranes are designed for high-salinity, warm seawater in UAE and GCC, delivering stable performance and reliable seawater reverse osmosis membrane operation.

Can these membranes be used in industrial RO systems?

Yes, SWC5LD and MAX membranes are compatible with industrial RO setups, delivering reliable performance in municipal and commercial desalination projects.

What sizes are available for SWC5 membranes?

SWC5 membranes are available in 4” and 8” sizes, supporting a wide range of industrial RO membrane and SWRO system requirements.