Finest screening/filtration holds significant importance in the last stage for cleaning water intakes, for protecting downstream equipment like pumps and condensers reliably against clogging. Dutco Tennant LLC supplies Travelling band screens having the most proven design variant that reduces the life cycle costs and efficiently extracts fine debris. Many of our supplied units have been running successfully at the site for more than four decades in the river and sew water applications. In comparison with the dual flow band screens, our supplied center flow band screens avoid the accumulation of debris under the machines that would be difficult for removing from the bottom of a channel.

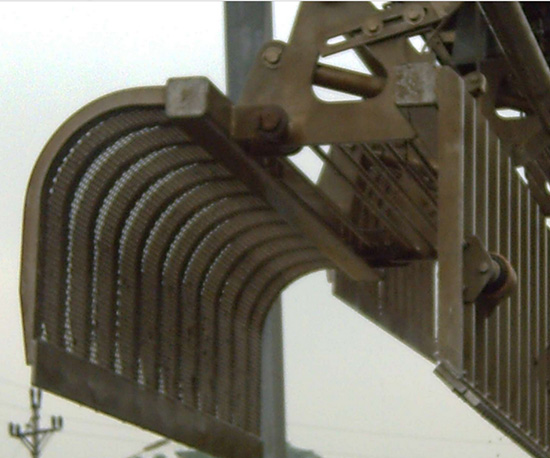

Automatically at the upper part, the spraying of the channel takes place and it follows the natural gravity direction which also minimizes the water leakages to the operation deck. Depending on the requirement of the site, the mesh panels are either roof/half-round shaped or are flat. With half-round or roof-shaped mesh panels, higher efficiency of the machine size can be achieved and bigger particles cannot drop back so easily. The maintenance-free sidebar chains are the special features that guide the mesh panels, a highly efficient, scale-like sealing between the screening elements, curved guidance, and chain as well as the chain track on the clean waterside. The adjustable band speed makes way for optimum adaption of screen washing and flow rate. By means of an intense washing, excellent cleaning of the mesh panels is achieved, the wash water system is adjustable and can be controlled via remote control. Traveling grab screens are highly recommended to be used for removing large quantities of debris and are preferred as coarse screens mainly in the high depth channels. They come with a cleaning grab which can move vertically and horizontally when the screens are very much wide or when it is desired for cleaning a large number of parallel screen channels. The cleaning mechanism is completely automatically operated and controlled by time or lever sensors. Manual operation is also available. We supply Travelling Grab Screens which are mainly made up of a supporting steel frame, pillar group supported monorail, grab unit, screen media, positioning sensors, and discharge unit. They are the most economical solutions available under the conditions that channel width is very high or it is required to clean several screen channels.

Features and Benefits

- Has no moving parts underwater

- Is suitable to be used in deep and wide channels

- Is designed to be compact

- Is available for multi-screen operation per one unit

- Has very high waste discharge capacity

- Possible for taking away screenings at a relatively higher distance

- Can be installed easily

- The operation and investment cost is low

- Time or level sensors maintain automatic cleaning

- The maintenance cost is low

Other Details

- Travelling grab screens are a type of the most suitable screens used to remove large quantities of debris, preferred as coarse screens especially in the high depth channels. They have a cleaning grab that can move horizontally and vertically when the sceens are too wide or when it is desired to clean a large number of parallel screen channels. The cleaning mechanism is full-automatically operated, controlled by time or level sensors. Manual operation is also possible. Travelling Grab Screens are mainly made up of a supporting frame in steel, monorail supported by a pillar group, screen media, grab unit, discharge unit and positioning sensors. They are the most economical solutions under the conditions that channel width is too high or it is required to clean several screen channels.

- Suitable for use in deep and wide channels

- No moving parts under water

- High waste discharge capacity

- Possibility to take screening away at a distance relatively high

- Available for multi-screen operation per one unit

- Automatic cleaning by time or level sensors

- Compact design

- Easy installation

- Low investment and operation cost

- Low maintenance cost