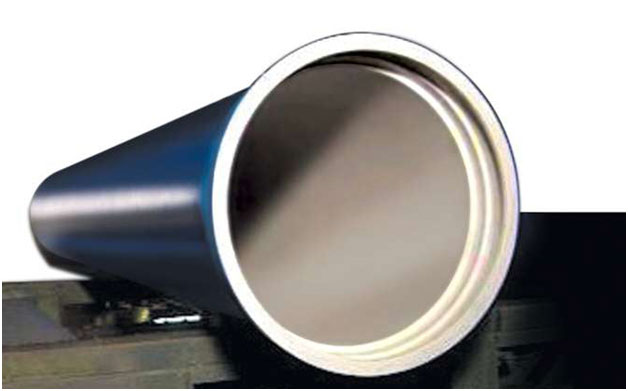

Ductile iron pipe(spigot and socket joint) is a pipe made of ductile cast iron commonly used for potable water transmission and distribution. This type of pipe is a direct development of earlier cast iron pipe.

Ductile cast iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethene or steel

Spigot and socket joint in pipes allowing water to be transported from its source to treatment plants and places of consumption. Our sewage solutions address water whether it is potable, raw, waste or recycled, and cover the entire water transport cycle, from its gravity supply, surface and groundwater filtration and seawater desalination, treatment and storage, and distribution to consumers and industry.

Advantages of Ductile Iron pipes(spigot and socket joint)

- The durability and resistance of ductile iron to pile driving, soil compaction and structural load.

- Fast, automatic assembly: fitted together using specific male and female conical ends.

- The reliability and durability of foundations with a rigid set of piles that are perfectly fitted together.

- They are the perfect solution for geotechnical requirements, combining friction effect and point effect to constitute effective and long-lasting ground reinforcement.

Ranges of Pipes

Ductile Iron Spun Pipes are produced in both as per Thickness Class (like, K9, K7 etc) and Pressure Class (Like C25, C30, C40 etc).

Ductile Iron Socket and Spigot Pipe with Push-On Joint from DN 80 to DN 1000 with Rubber Gasket conforming to IS 8329/ ISO 2531/ EN 545/ EN598 for Drinking Water and sewerage. Ductile Iron pipes are available in the following Joints.

- Ductile Iron Socket and Spigot Pipe with push-on joints& push- on joints(restrained)

- Ductile Iron plain-ended Barrel Pipes

- Ductile Iron Socket and Spigot Restrained joint pipes with Push-on rubber gasket Joint

- Ductile Iron Flanged Pipes of standard and customized length.

Benefits

- Fully Coated and Lined with a cement inside & bitumen coated outside

- Corrosion Resistant.

- Certified to comply with WRAS

- The life expectancy of Ductile iron pipe is unknown but is estimated to be 100 years or more

- High structural strength, and tight joints, ductile iron is also readily machinable, an important requirement in any pipe that must be drilled, tapped, or cut