Mixing and containing plays a very important role in the field of water treatment and can have a fundamental influence on the performance of individual process stages and even hamper the results of the entire process itself. The demand for continuous improvement of the cleansing processes increases rapidly due to the ever-increasing demands on water quality. This makes way for a heightened increase in general use in-line static mixers which are used for mixing and contacting operation in this sector.

In a process stream, static mixers are installed in-line for mixing and contacting operations. The associated conduit or pipe can have several shapes from square, to rectangle to round and are available in several designs and in a variety of materials that enables optimum adaptation for meeting individual process requirements. In water treatment, for instance in potable water, it is preferred to used SMV mixer for both mixing gas and liquid mass transfer procedures. However, during mixing operations in which the media involves contained solid particles particularly fibers, the plugging of the mixer can occur. In circumstances like this, the use of the specially developed SMF mixer is highly recommended. The SMF mixing elements comprises of inclined vanes that can cross without coming in contact with each other and are completely open to the flow stream from all sides. This mixer type is therefore not susceptible to plugging and is being used with success in the treatment of sludge and wastewater. A static mixer comprises basically a sequence of stationary guide plates that results in the radial and systematic mixing of media that flows through the pipe. A geometrical pattern is followed by the flow path that precludes any random mixing. The mixing operation is, therefore, gets completed within a very short flow distance. the formation of fine gas bubbles inside the water/gas mixture promotes intensive contact between the two phases. This results in high mass transfer, for instance, a high oxygen transfer rate or an excellent ozone utilization factor. Contrasting to the stirred tanks or empty pipe systems, guaranteeing that the complete fluid stream is subjected to compulsory or enforced mixing or contacting is done by static mixers. The amount of energy that is required for mixing or for mass transfer is taken from the mainstream itself, which is manifested by an excellently higher pressure drop than in an empty pipe system. Dutco Tennant LLC supplies a superior range of Static Mixers for Wastewater. We have two types of Static Mixers for Wastewater like Non-Ragging Pipe Mixers for Wastewater and the Non-Ragging Channel Mixers for Wastewater.

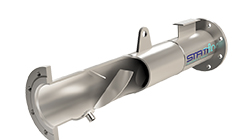

Non Ragging Pipe Mixers for Wastewater

Non-Ragging Channel Mixers for Wastewater