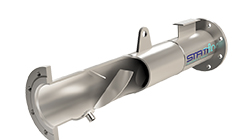

A non-ragging static channel mixer for dosing additives into wastewater including raw sewage. The Statiflo NRC Mixer has been designed specifically for P removal applications but can equally be used on any chemical dosing service on raw sewage where non-ragging properties are essential. It has a unique variable geometry custom designed for the widest range of wastewater velocities and channel depths found on a typical wastewater treatment plant.

The mixer’s non-ragging design features:

•Variable angle control vanes tuned to optimise performance within tight headloss constraints

•Manual or automatic (power required) control vane options

•Integral accessible sparger for chemical injection

•Subsurface fixed vanes to boost mixing at low depth

•Designed for easy installation in live open channels

•Design adaptable for a wide range of channel sizes, aspect ratios, water depths and flowrates

•No direct power requirements for mixing

The mixer’s non-ragging design features:

•Variable angle control vanes tuned to optimise performance within tight headloss constraints

•Manual or automatic (power required) control vane options

•Integral accessible sparger for chemical injection

•Subsurface fixed vanes to boost mixing at low depth

•Designed for easy installation in live open channels

•Design adaptable for a wide range of channel sizes, aspect ratios, water depths and flowrates

•No direct power requirements for mixing

Other Details

- Upgrading from commonly occurring dosing, using an open ended pipe, to a Statiflo NRC Mixer will provide many process benefits:

- Very significant chemical savings

- Improved primary sedimentation tank performance

- Reduced BOD load

- Higher sludge concentrations

- Reduced Fe concentration in final effluent / sludge

- Reduced or eliminated channel staining

- Substantial cost savings

- The Statiflo Non-Ragging Channel Static Mixer uses the same mixing technology as the Statiflo Non-Ragging Pipe Mixer, with customised geometry suitable for a channel

- The minium channel size available is 0.3m wide x 0.3m depth but there is no maximum limit on size. Statiflo have supplied some of the largest static mixers in the world, with current installation ranging all the way up to 7m wide x 5m depth

- Whether the channel or duct is square, narrow and deep, wide and shallow, or anywhere in between Statiflo’s specially developed modual element design means a suitable solution can be offered for any space requiring mixing

- Mixers available in all commercial available metallic materials including stainless steel, Alloy C276 or high grade duplex and super duplex stainless steels

- Adequate acquisition costs compared to other methods

- Extremely easy installation

- Low operating costs

- Consistent performance even with fluctuations in the amount of water

- Minimal space requirement

- Closed system

- Self-cleaning

- Available in all sizes

- Can also be used in channels and chambers

- Available in all materials

- Designed according to the customer’s needs

- To be manufactured according to all standards (AD2000, ASME, PED etc.)

- Available worldwide