Wet packed scrubbers for the removal of corrosive, noxious and odourous gases from airstreams. Designed for high collection efficiency, maximum corrosion resistance. Scrubber design is characterized by low liquid irrigation rates, high volume air flow and low pressure drop.

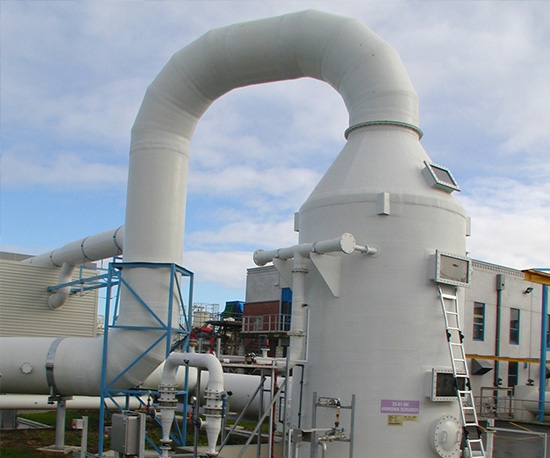

Traditional vertical countercurrent scrubbers offer the best mass transfer capabilities with the smallest footprint. The scrubbing liquid is irrigated at the top of the scrubber, and cascades down through the packing countercurrent to the gases. A scrubber sump is incorporated into the bottom of the vessel.

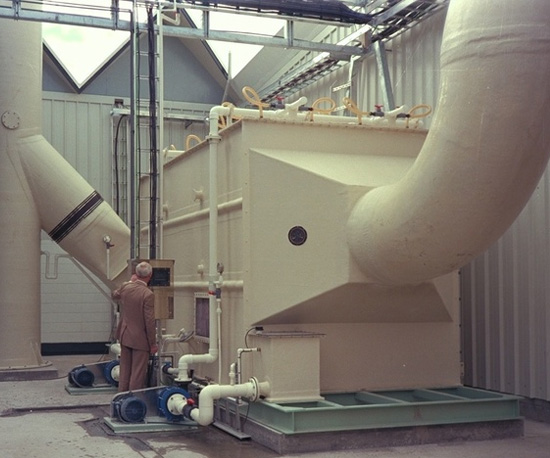

Horizontal crossflow scrubbers can offer advantages in some plant layouts by minimising ducting requirements. They are ideal when there are two separate scrubbing vessels with different chemicals; the two beds are incorporated into the same housing but are separated internally.

Wet packed scrubbers are usually packed with Tellerette tower packing for best efficiency. Wet packed scrubbers are manufactured under licence to Verantis of the USA.

Traditional vertical countercurrent scrubbers offer the best mass transfer capabilities with the smallest footprint. The scrubbing liquid is irrigated at the top of the scrubber, and cascades down through the packing countercurrent to the gases. A scrubber sump is incorporated into the bottom of the vessel.

Horizontal crossflow scrubbers can offer advantages in some plant layouts by minimising ducting requirements. They are ideal when there are two separate scrubbing vessels with different chemicals; the two beds are incorporated into the same housing but are separated internally.

Wet packed scrubbers are usually packed with Tellerette tower packing for best efficiency. Wet packed scrubbers are manufactured under licence to Verantis of the USA.

Uses of Wet Packed Scrubbers

•Chemical Plants for noxios gas control

•Waste water treatment plants for odour control

•Rendering plants for odour control

•Tanneries for hydrogen sulphide control

•Pulp & Paper plants for noxious gas control

•Particle Board plants for formaldehyde control

•Food processing plants for odour control

•Waste water treatment plants for odour control

•Rendering plants for odour control

•Tanneries for hydrogen sulphide control

•Pulp & Paper plants for noxious gas control

•Particle Board plants for formaldehyde control

•Food processing plants for odour control

Features

- Food processing plants for odour control

- Particle Board plants for formaldehyde control

- Pulp & Paper plants for noxious gas control

- Tanneries for hydrogen sulphide control

- Rendering plants for odour control

- Waste water treatment plants for odour control

- Chemical Plants for noxios gas control

- Sufficient contact-time in combination with a limited air velocity through the packed bed guarantees a low chemical consumption

- A substantial recirculation flow to guarantee a good contact between air and water phase to induce the chemical reaction

- A new technology of dosing the chemicals. Chemicals are no longer dosed constantly with a constant bleed of unused chemicals. In IPEC scrubbers, the chemicals are dosed based on the actual need. Therefore, using a PLC there is a constant monitoring of the H2S level before and after the scrubber in combination with a monitoring of the pH of the recirculating liquid (and ORP monitoring in case of bleach dosing)