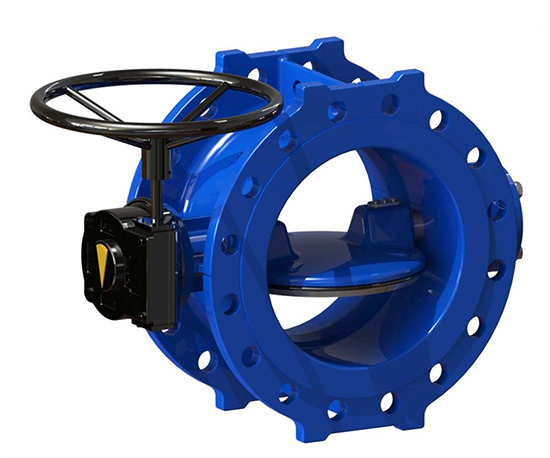

Double eccentric valves are also common names as high-performance butterfly valves and they are characterized by their long service time, low maintenance and reduced friction between the seal and the gasket. Their first eccentric valve is the offset between the shaft centerline and the disc trunnion centerline. The offset between the body center line and the disc centerline is the second eccentric. Excellent controllability, bubble-tight shut-off, and smooth operation and reduced flow resistance are offered by the design.

We have an extensive range of Double Eccentric Valves which includes Resilient and Metal seated Valves. Our supplied valves exceed the market standards because of outstanding features like the optimized seal design and the corrosion protected shaft end zones. These butterfly valves offer longer service life due to tilted disc. The tension on the disc is released after a few degrees of the opening which minimizes wear of the disc seal. The compression of the sealing is further minimized by the design which ensures low operating torques. By the means of a key and a keyway, the disc and shaft are connected. The key is secured with two set screws for preventing flutter caused by flow velocity and necessary play in the key and keyway connection. The disc is secured with two stainless and steel drive dowels with key and keyway as a back-up in case of large dimensions.

The integral seat design has a machined and epoxy coated ductile iron seat integrated into the body. The stainless steel seat design comes with a replaceable seat ring of stainless steel sealed with an O-ring to avoid leakages under the seat ring. Under pressure, the shaft sealing is replaceable to enable easy maintenance. Tightness is secured from inside and out due to EPDM sealing and protection against impurities and fluids from outside is offered by NBR sealing. The valves are also fitted with a locking device which makes it possible to lock the disc in the open and closed position if gearbox replacement becomes necessary.

Features

- Optional locking device.

- Seal retainer ring of epoxy coated steel.

- Shaft of stainless steel with self-lubricating bearings.

- The disc is fixed to the shaft to prevent wear and fluttering.

- The disc seal profile and rubber quality ensure low closing torques.

- Machined and epoxy coated ductile iron seat integrated in the body.

- The threaded bolt holes in the disc are corrosion protected with O-rings.

- The double offset disc of double eccentric butterfly valve design ensures minimal seat wear and provides excellent throttling capabilities.

- An adjustable mechanical stopper provided on the valve body ensures the precise closing of the disc without over/under travel.

- Both drive end and non-drive end shafts are fully blowout proof and guided by self-lubricated bush bearings.

- Axial thrust bearing provided on valve ensures precise positioning of the disc and prevents unequal loading of the valve seat, it also enables the installation of the valve in any orientation of required.

- The tilted disc releases the compression of the disc sealing after a few degrees of opening, which extends the durability and gives low operating torques.

- The shaft ends are fully encapsulated in the disc and are fixed with dowels corrosion protected with O-rings and a stainless steel security plate. Key and keyway as backup.

- Replaceable shaft sealing with two EPDM O-rings on each side of a bronze bushing, and a flat NBR gasket.