.png)

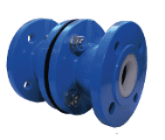

Dzr brass parallel ends - double check valve can prevent the reverse flow of the polluted water from getting inside the supply of potable water at the individual outlets or service entrance. They are having a Lead-Free Cast Copper Silicon Alloy construction body having two plastic replaceable check valves along with stainless steel spring. They have been designed for residential non-hazard water system containment, continuous pressure applications and are immediately installed on downstream of the residential water meter inside a horizontal or vertical position. You can check with the local authorities of inspection for the requirements of the installation.

The check valves are designed for allowing the flow of fluid only in one direction. They are having two ports one of which works as an inlet for the medium and the rest works as the medium output. As they allow the flow of media only in one direction, they are mostly known as non-return or one-way valves. The main job of the check valves are to prevent the backflow inside the system. These valves mostly rely on a pressure differential for working. They are in need of much higher pressure on the input side of the valve compared to the output side for opening the valve. When the outlet pressure is higher, the valve gets closed. Depending on the type of the valve, the mechanism for closing is different. Unlike other valve types, they are not in need of a lever, handle, actuator or manual labor to work correctly. Commonly, these valves are installed over applications which would cause backflow an issue. But being non-return valves, they are effective, cheap and easy solutions for solving potential issues. Backflow can create an issue if it gets contaminated and the media upstream can get contaminated. Dzr brass parallel ends - double check valves need to be maintained regularly which is the most efficient way for guaranteeing a longer operational period and efficiency. Such types of programs need to include an assessment of the risk involved along with a planned procedure about how the maintenance will be taking place. The possibilities of the operational limits may exceed and the potential hazards also ensure should be considered being a part of this assessment. This is required for implementing for including a visual check over the condition of the valve and any development of the unforeseen conditions that can lead to failure. The correct fitting tools and the equipment may be used for the maintenance of the valve. Separate measures of draining the piping work should be offered while carrying out any maintenance of the valves. In cases where there is debris in the system, this can be filtered or collected by installing a suitable protective device.

Features

- Screwed BSP Parallel (ISO 228/1)

- WRAS Approved

- Conforms with EN13959

- Prevention of back flow and back syphonage contamination

Technical Data

| Max Pressure | 16 Bar |

| Working Temperature | -10ºC to +85ºC |