Efficient Wastewater Treatment Mixers for UAE and GCC

Efficient wastewater management is essential for operational reliability and environmental compliance. Dutco Tennant LLC supplies wastewater treatment mixers and submersible mixers for wastewater that ensure uniform mixing, enhanced oxygen transfer, and optimized performance in municipal, industrial, and effluent systems across the UAE and GCC.

Our range of industrial mixing equipment, including the MX II stainless mixer and other stainless steel mixers, supports biological treatment processes such as denitrification, prevents sedimentation, and eliminates dead zones in effluent tanks.

These effluent tank mixers provide reliable fluid motion and energy-efficient operation, ensuring smooth wastewater treatment while reducing foul odors and minimizing operational downtime.

Engineering & Operational Excellence

Dutco Tennant's high efficiency submersible agitators and horizontal submersible mixers are engineered for precision and durability:

- Optimized Submersible Mixers: Enhance aeration, maintain uniform suspension, and support effective sewage mixing solutions.

- Stainless Steel Mixers: Corrosion-resistant design ensures long-term durability in aggressive wastewater environments.

- Custom Configurations: Adaptable for various tank sizes, depths, and wastewater types.

- MX II Stainless Mixer: Eliminates dead zones and ensures even oxygen distribution across the tank.

Performance Highlights

Our wastewater treatment mixers deliver consistent, reliable operation:

- Uniform Suspension of Solids: Maintains even distribution of suspended particles in effluent tank mixers.

- Energy-Efficient Operation: Reduces power consumption for continuous wastewater treatment.

- Supports Biological Processes: Optimizes denitrification and other essential treatment steps.

- Anaerobic Zone Prevention: Minimizes foul odors in sewage mixing solutions.

- Industrial-Grade Reliability: Suitable for continuous operation in municipal, industrial, and effluent systems.

Types

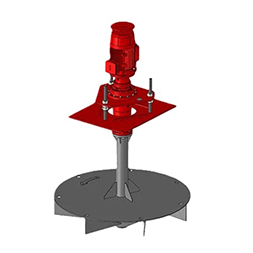

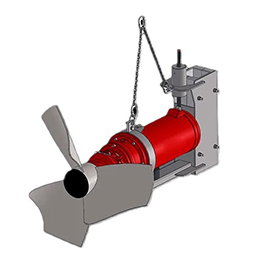

Submersible Mixers for Wastewater

Designed for deep tanks and irregular wastewater systems.

- Supports high oxygen transfer and efficient sewage mixing solutions.

- Reduces dead zones and sedimentation in effluent tanks.

- Ideal for municipal, industrial, and utility applications.

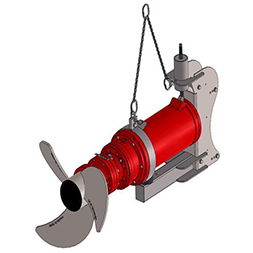

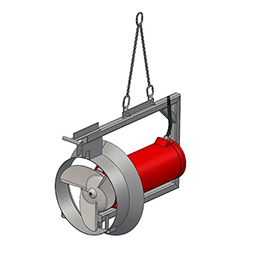

Horizontal Submersible Mixers

Engineered for large tank environments requiring consistent horizontal flow.

- Maintains uniform suspension of solids in wastewater treatment mixers.

- Enhances biological and chemical treatment efficiency.

- Suitable for municipal and industrial effluent systems.

Industrial Mixing Equipment

Robust effluent tank mixers for industrial wastewater treatment.

- Supports denitrification and pollutant breakdown.

- Handles aggressive industrial and municipal effluents.

- Designed for continuous operation with low energy consumption.

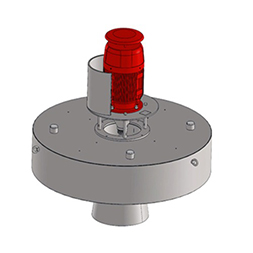

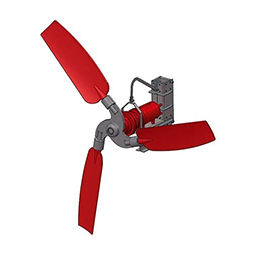

MX II Stainless Mixer

High-efficiency agitator built for precise tank homogenization.

- Corrosion-resistant stainless steel mixer for long-term operation.

- Ensures even oxygen distribution and sediment prevention.

- Compatible with various wastewater treatment mixers and effluent tank types.

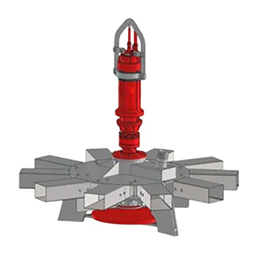

Denitrification Mixer Units

Specialized units to enhance biological nitrogen removal.

- Supports optimized denitrification processes in sewage mixing solutions.

- Prevents anaerobic zones and foul odors.

- Suitable for municipal, industrial, and effluent wastewater treatment.

Standout Features & Benefits

Optimized Mixing Efficiency

- Enhances oxygen transfer in all wastewater treatment mixers.

- Prevents dead zones and ensures uniform effluent tank mixing.

- Supports denitrification and other biological treatment processes.

Durable Stainless Steel Construction

- Long-lasting stainless steel mixers withstand aggressive effluents.

- Suitable for continuous use in industrial and municipal wastewater systems.

- Maintains reliable operation in harsh environmental conditions.

Energy-Saving Design

- High-efficiency submersible mixers for wastewater reduce energy consumption.

- Designed for continuous operation without compromising performance.

- Lowers operational costs while improving overall wastewater treatment efficiency.

Application Area

Wastewater Treatment Plants

- Ensures uniform mixing of municipal and industrial effluents.

- Supports biological treatment including denitrification with effluent tank mixers.

- Prevents anaerobic zones and foul odors.

Industrial Effluent Tanks

- Efficiently mixes chemicals and industrial wastewater using horizontal submersible mixers.

- Optimizes pollutant breakdown and treatment efficiency.

- Suitable for continuous operation in large-volume tanks.

Desalination and Leachate Facilities

- Pre-treatment mixing with industrial mixing equipment ensures efficient chemical use.

- Prevents stratification and enhances pollutant removal.

- Improves overall operational reliability.

Cooling Water and Stormwater Systems

- Ensures even chemical distribution and prevents biofouling with high efficiency submersible agitators.

- Maintains sediment suspension in stormwater retention tanks.

- Supports consistent water quality in cooling and stormwater applications.

Healthcare, Dairy, and Livestock Wastewater

- Efficiently mixes disinfectants and effluents for sewage mixing solutions.

- Aids biogas generation and reduces odors in livestock or dairy effluents.

- Ideal for hospitals, dairy plants, and livestock facilities.

FAQ

What are submersible mixers for wastewater used for?

They ensure uniform mixing, enhanced oxygen transfer, and prevent dead zones, supporting efficient biological treatment and reducing operational downtime in effluent tanks and sewage systems.

How does the MX II stainless mixer improve wastewater treatment?

It provides consistent fluid motion, prevents sedimentation, ensures uniform oxygen distribution, and supports denitrification, enhancing overall effluent treatment efficiency.

Can horizontal submersible mixers be used for industrial effluent tanks?

Yes, they maintain uniform suspension, improve biological and chemical treatment, and handle aggressive industrial effluents efficiently.

Are these wastewater treatment mixers energy-efficient?

Yes, high-efficiency submersible agitators reduce power consumption while maintaining consistent mixing performance even during continuous operation.

Do these mixers help reduce foul odors?

Yes, by eliminating anaerobic zones and enhancing oxygen transfer, sewage mixing solutions reduce foul odors and improve wastewater quality.

Can denitrification mixer units support nitrogen removal?

Yes, they optimize biological treatment, supporting efficient denitrification processes and maintaining proper oxygen distribution in wastewater tanks.

Are these stainless steel mixers suitable for marine or port wastewater?

Yes, corrosion-resistant MX II stainless mixers efficiently mix effluents from ships, offshore platforms, and onshore marine facilities.

Can these mixers be customized for different tanks?

Absolutely, Dutco provides custom industrial mixing equipment configurations to ensure optimal mixing for various tank sizes, shapes, and wastewater characteristics.