Mechanical screening is done by industrial wastewater plants as the primary step in the process of wastewater treatment. By removing the larger solids from the wastewater, the mechanical screens protect the equipment in the treatment stages which follows. The screen type that is more suitable for a particular application relates specifically to the size and type of solids in the wastewater. For instance, sticky solids can require the use of a drum screen while the larger solids can just require a standard screw screen.

Dutco Tennant LLC offers you a complete line of mechanical screens ranging from Plastic Conveyor Screens, Screw Screens, Step Screens, Basket Screen, Wastewater Pretreatment Travelling Perforated Screens. With us, you can also get specially made compact screen units that can assist with the combined removal of oil, sand, grease, fibers, and solids all in a single process step. All of our supplied mechanical screens are made by our manufacturing partners using the most updated technology and quality standards. In comparison with several other mechanical pre-treatment systems in the market, our mechanical screens have unique advantages and features. These comprise higher treatment efficiency, triple seals for preventing any bypass of wastewater and completely automatic operation with custom made control panels and sensors. When you are choosing the right screen, it is the first step for successful wastewater treatment and it ensures the protection and continuous operation of the downstream assets. We have a massive range of mechanical screens that can be integrated into any existing onsite infrastructure and they can be installed within the existing pump stations.

Static screens are proven to be a highly reliable performer for separation of liquid from solids in municipal and industrial applications mainly for screening fibrous and non-greasy solids. There are no moving parts, motors, or complicated connections present. The static screen is simple and is very economical to operate. It is one of the most basic but is designed with quality and custom features for meeting the site requirements. The linear mechanical screens are automatic self-cleaning front raked inclined screens which are used as both coarse and fine screens in several kinds of treatment plants and pumping stations. They are the most preferred equipment as they have relatively few mechanical components and generally have no moving parts which need to be permanently located under the water level. The curved screen known as mechanical arc screens is used mostly as fine and coarse screens specially developed for medium and small-sized sewage treatment plants and water intake structures. They come with an automatic cleaning system that consists of one or more revolving rake assemblies. Generally, they are preferred for low-level channels because of their basic mechanisms. Mechanical arm screens are mostly made up of screening media, frame, drive unit, discharge chute, and counter wipe. If you require any types of Special Custom Made Screens for Wastewater Pretreatment then Dutco Tennant LLC has the best choice to offer you with.

Static Screens for Wastewater

Linear Mechanical Screens for Wastewater

Mechanical Arc Screens for Wastewater

Plastic Conveyor Screens for Wastewater

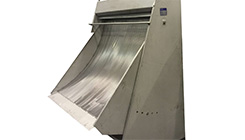

Screw Screens for Wastewater Solutions

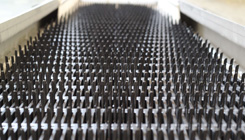

Step Screens for Wastewater

Basket Screen for Wastewater

Wastewater Pretreatment Travelling Perforated Screens