Tactile Indicators - Ensuring Independent Movement In Public Spaces

Every day, thousands of people walk on the roads, pedestrian crossings, public transport stations and sidewalks.

How many times do we notice the ground beneath our feet?

And even if we do,

How much do we understand the logic behind the design?

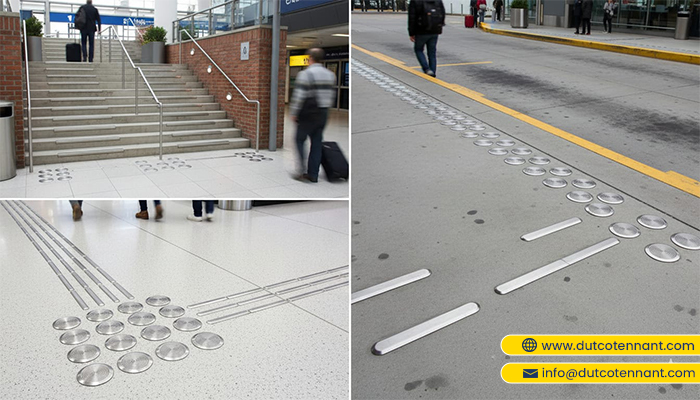

The network of tiles, joints and ridges that we seldom notice all have certain engineering logic behind them. One of these understated road features is tactile indicators, the raised studs and strips that make movement easier for people with partial or total vision impairments.

In busy spaces, such platforms are laid to ensure independent movement for specially-abled people, who walk with the support of canes and sticks. As they navigate the world through senses of touch and instinct, such designs help them move confidently.

What Are Tactile Indicators And How They Function

Also known as Tactile Ground Surface Indicators, or TGSI, raised studs are placed carefully on roads and sidewalks with a noble purpose. These are made of hard and durable materials, like stainless steel, brass, aluminum or PVC for stability and consistent interactions with sticks and canes.

The entire system is laid uniformly with these common features:

- Raised bars to indicate direction and encourage seamless navigation

- Circular studs as warning signs for potential hazards

- Color or contrast variations for partially-sighted commuters

Whenever someone feels textural changes under feet, he/she stops and gets aware of the route, thus ensuring safe movement. Blending tactile studs, strips and visual contrast, these systems help the flooring transform into a navigational tool for visually-impaired pedestrians.

Integrating Safety Into Every Unsure Step

Public transport spaces tend to have a continuous flow through slopes, curves, platforms and crossings. Instinctive movement is necessary in these high-traffic areas, especially for people with vision imbalances. Even the elderly people need extra help to step confidently.

With tactile warning strips, it becomes easier for them to stay independent and walk with dignity. These invisible geometries on the road beneath their feet gives them the much-required guidance to travel without any human assistance.

From their first step towards a bus station to boarding a train, these subtle cues work in sync to give them an idea about directions, potential hazards and stops.

Some common areas where you can see the indicators are:

- Bus bays and curb ramps, where the feet meet moving vehicles

- Train and metro platforms to mark safe zones effectively

- Large open spaces, like airports, with separate entry and exit points

- Staircases, elevators and escalators, where guided movement is mandatory

When designed accurately and installed properly, the indicators act as life saviours besides being an efficient navigation guide. They create a rhythm of trust, balance and independence beneath the feet.

What To Consider While Installing Tactile Indicators

Every module should be placed after careful planning and so that they communicate effectively with the people who rely on them. Even a deflection of some milimetres can put safety at risk, jeopardising the pedestrian’s life.

Some principles that the installation process must adhere to are:

- Ensuring consistency - The patterns should remain uniform in a space, so that the commuters need not learn the cues at every step.

- Placing the strips properly - The warning studs and strips should be placed in alignment with real hazard zones. With minimum decoration, navigational strips should lead naturally to entry and exit points.

- Maintaining color contrast - The elderly people and those with partial visual impairments can detect colour cues. Hence the systems should utilise luminance and contrasts effectively during installations.

- Choosing the right materials - Exposure to the environment, foot and vehicular traffic impacts the durability of the metal strips. Using corrosion-resistant materials, like stainless steel, brass, aluminum or PVC can keep performances reliable over a longer duration.

- Ensuring slip resistance - In high-traffic zones, proper finishes ensure slip-resistance. Care should be taken not to affect the sensitivity of the tactile indicators though.

- Regular maintenance - Every strip and stud are exposed to dust, heat, moisture, polish, floor wax continuously. Regular cleaning is needed to ensure they keep performing as intended.

The Silent Promise Beneath Every Feet

This road safety system only works as expected when they are installed properly across public transport areas. From choosing the right materials to placing the systems, every decision is backed by meticulous planning and proper implementation.

At Dutco Tennant LLC, we analyse how people move in a given area, potential stops and hazard areas before providing the ideal systems that would help navigation.

Our tactile warning strips and indicators are chosen based on:

- The area to be covered

- Layout assessment

- Selection of materials

- Spacing and alignment

- Size and shape of strips and studs

- Visual optimisation

Note: We don’t allow even the slightest of deviation, thus ensuring 100% safety in performance. At Dutco, we treat these elements as the ‘silent promise under feet’, something that aligns with instinct, building reliance and independence at the same time.

Are you planning to cover a space with tactile indicators? Connect with our sales team to get the perfect design, layout and materials.