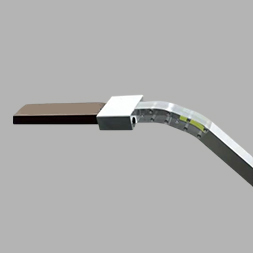

Easy Bar Lubricator Insertion Tool for Kiln Operations

The Easy Bar Lubricator Insertion Tool is supplied by Dutco Tennant LLC as a safer and efficient solution for inserting high temperature lubricant into rotary kiln systems. This tool supports consistent lubrication during kiln operation by offering controlled placement of lubricant bars without exposing the operator to extreme heat zones.

Designed for environments requiring lubricant high temperature performance, this Easy Bar insertion tool helps improve lubrication accuracy and supports safe handling during uphill side lubrication tasks. It is widely trusted in sectors using high-heat rotary equipment, including cement, pulp and paper, mining, glass, waste processing, and industrial thermal applications across the UAE and GCC.

This easy bar application tool works smoothly with lubricant bars used in riding rings, trunnion bearings, and rotary kiln tires. Its simplicity supports lubrication technician safety by providing reach, balance, and controlled material application. Whether applied during shutdown or live lubrication, the tool supports consistent results in demanding operating environments, making it an ideal lubrication solution.

Operator Safety Advantage

- Designed to help reduce exposure to hot rotating equipment during lubrication tasks.

- Allows controlled placement of high temperature lubricant with added reach and precision.

- Helps avoid risky direct handling when performing uphill side lubrication.

- Supports confident handling for both new and experienced lubrication technicians.

Reliable Lubrication Support

- Suitable for rotary kiln lubricator use where precise location accuracy is required.

- Helps ensure lubricant bar contact at the correct angle and pressure during insertion.

- Compatible with multiple kiln setups requiring periodic bar-based lubrication.

- Performs consistently in high-temperature rotary environments.

- Built to withstand demanding industrial working conditions.

Types

Standard Easy Bar Insertion Tool

A general-use kiln lubrication tool suitable for continuous rotary kiln environments.

This version supports simple manual lubrication procedures where operators require improved reach, balance, and application consistency.

- Easy to transport and operate

- Suitable for different kiln sizes

- Works with lubricant high temperature bars

Extended-Reach Lubricator Tool

Designed for deeper insertion into wider or larger rotary systems.

Often used in cement kilns, ore processing kilns, and other installations where additional clearance distance and control support operator safety.

- Ideal for larger kilns

- Enables safer working distance

- Supports heat-intensive systems

Precision Insert Type

Used in kilns requiring highly accurate lubrication points.

Supports installations where incorrect application placement can impact component function, lubricant spread, or equipment temperature stability.

- Helps deliver precise lubricant contact

- Reduces chance of misalignment

- Suitable for experienced lubrication teams

Heavy-Duty Kiln Bar Installation Tool

A reinforced version built for abrasive and rugged environments.

Common in mining, thermal processing, and high-throughput production plants requiring durable industrial lubrication tool designs.

- Strong materials for harsh sites

- Suitable for high-output rotary systems

- Long-term operational durability

Standout Features & Benefits

Improved Safety Handling

- Helps prevent unnecessary proximity to hazardous heat zones.

- Supports safer procedures during active kiln lubrication events.

- Suitable for demanding industrial environments.

Ease of Use

- Requires minimal training to operate effectively.

- Offers straightforward handling for lubrication technicians.

- Lightweight construction enables easy field mobility.

Consistent Lubrication Contact

- Helps ensure steady contact of lubricant bars with target components.

- Improves lubrication consistency across multiple operational cycles.

- Suitable for uphill side lubrication and rotational contact points.

Application Area

Cement and Mineral Processing

- Supports cement kiln lubrication tool requirements for trunnion and tire contact points.

- Fits large, high-temperature equipment used in clinker production.

- Suitable for GCC-based cement operations.

Mining and Industrial Plants

- Works with rotary dryers, calciners, and ore roasting systems.

- Supports abrasive site conditions requiring rugged tools.

- Suitable for heavy processing environments.

Thermal and Energy Facilities

- Ideal for rotating combustion chambers and waste-to-energy equipment.

- Supports systems using solid fuels and high-heat burners.

- Enhances operator confidence in high-temperature lubrication zones.

FAQ

How is the Easy Bar insertion tool typically used?

It is inserted near the lubrication contact point, allowing technicians to guide lubricant bars safely into rotary kilns during operation.

Is this tool suitable for all rotary kiln sizes?

Yes, most models are compatible with various kiln sizes, and extended-reach options support larger or deeper access environments.

Can this tool be used with different lubricant formats?

It is primarily designed for solid lubricant bar products compatible with high-temperature rotary machinery.

Does the tool support uphill side lubrication?

Yes, the tool enables controlled uphill side lubrication during rotation, improving safety and consistency.

Is training required to operate the tool?

Only basic familiarization is needed, making it suitable for new users and experienced lubrication technicians.

Can it be used while the kiln is rotating?

Yes, it is specifically designed to assist lubrication during live operations where controlled insertion is required.

Is the tool suitable for outdoor industrial environments?

Yes, it is built for demanding industrial environments including heat, dust, and abrasive work zones.

Can this tool reduce downtime during lubrication tasks?

Yes, by allowing faster and more accurate lubrication, the tool helps maintain smoother operation and process continuity.