Modular Support Systems for Construction and Industrial Projects

Dutco Tennant LLC supplies innovative modular support systems across the UAE and GCC, engineered in partnership with Link Yapi, Turkey. These systems provide reliable load-bearing capability, flexible installation, and long-term durability for demanding project environments.

As infrastructure and industrial development continues to evolve, the requirement for adaptable, safe, and high-performance structural support systems has increased significantly. From formwork support and modular shoring systems to pipe hanger support and MEP support systems, these engineered framing solutions ensure operational efficiency and long-term reliability.

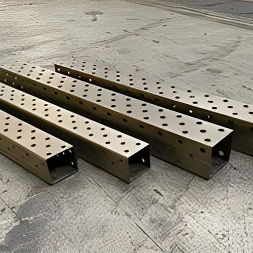

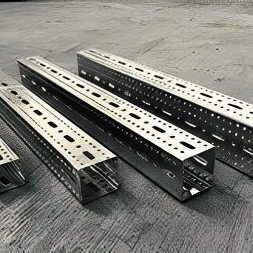

Designed as bolt-connected, non-welded support structures, these modular framing systems simplify installation while ensuring maximum structural stability. The PROCON support system enables quick reconfiguration, allowing seamless adaptation to MEP installations, modular steel frame construction, and industrial support requirements.

Customizable Engineering for Modern Installations

- These modular support systems allow flexible adaptation to various architectural and industrial layouts without requiring heavy modification.

- Ideal for fast-paced construction workflows where tool-free adjustability and rapid assembly offer significant time savings.

- Designed to support piping, cable trays, HVAC systems, and structural loads in commercial, industrial, and infrastructure developments.

- Ensures long-term reliability with durable steel framing components resistant to corrosion and environmental exposure.

- Suitable for small installations and large-scale industrial support systems with scalable configuration options.

Built for Industrial Strength and Long-Term Efficiency

- The PROCON support system offers high-strength modular steel supports for piping and heavy infrastructure requirements.

- Compatible with MEP support systems, formwork scaffolding, props shuttering, and adjustable support props.

- Available in aluminum, stainless steel, and galvanized steel variants to meet diverse project conditions and regulatory standards.

- Designed to offer safe reinforcement in seismic zones with support for seismic restraints and vibration-sensitive environments.

- Enables repeated use, helping reduce long-term cost, material waste, and total installation effort.

Types

Modular Framing System

A flexible system designed for MEP installations, supporting cable trays, ducts, and piping layouts in commercial or industrial projects.

- Quick assembly using bolt-connected components

- Scalable and reconfigurable structure

- Eliminates welding and heavy fabrication

Modular Steel Supports for Piping

Engineered for safe support of industrial piping systems, ensuring structural stability and load-management efficiency.

- Suitable for high-temperature and high-pressure lines

- Compatible with mechanical and HVAC systems

- Designed for long-term corrosion resistance

Adjustable Support Props

Best suited for temporary or permanent reinstatement where height flexibility and high load capacity are required.

- Ideal for construction props and formwork support

- Easily repositioned for varying site conditions

- Strong and durable with minimal maintenance needs

Modular Shoring Systems

Provides reinforcement for structural construction, including formwork scaffolding and slab support in major developments.

- Designed for rapid setup and removal

- Stable and secure load-bearing capacity

- Compatible with multiple structural configurations

Stainless Steel Support System

Intended for environments requiring high corrosion resistance such as chemical plants or marine infrastructure.

- Minimal maintenance requirements

- High durability in demanding conditions

- Suitable for sterile or sensitive facilities

Standout Features & Benefits

Rapid Installation

- Bolt-based assembly eliminates welding and special tools.

- Reduces installation timelines and labour cost.

- Ideal for fast-track construction environments.

High Structural Strength

- Supports heavy loads efficiently without deformation.

- Suitable for long-term industrial and infrastructure projects.

- Offers tested and certified stability.

Long-Term Cost Efficiency

- Reusable design reduces long-term purchasing requirements.

- Easy to modify or expand as project demands change.

- Low maintenance over lifecycle.

Versatile System Design

- Compatible with multiple industrial applications and layouts.

- Supports both temporary and permanent structures.

- Configurable for custom project requirements.

Application Area

Construction and Infrastructure

- Used for formwork support systems, props shuttering, and modular shoring systems in large-scale developments.

- Ideal for airports, metro stations, high-rise buildings, and industrial complexes.

- Enhances build speed and operational safety.

MEP Installations

- Supports HVAC ducts, cable trays, and modular pipe support systems.

- Ensures organized routing and maintenance access across facilities.

- Suitable for both commercial and industrial properties.

Industrial Facilities

- Designed for power plants, manufacturing units, oil and gas sites, and water treatment plants.

- Offers durable support for dynamic or heavy machinery loads.

- Maintains stability in vibration-intensive environments.

Modular and Prefabricated Construction

- Ideal for modular steel frame construction and prefabricated structures.

- Ensures accurate alignment and long-term reinforcement.

- Suitable for fast-deployment environments.

FAQ

What makes modular support systems better than traditional welded structures?

These systems allow faster installation, adjustability, and reuse while remaining strong and corrosion-resistant, reducing long-term installation and maintenance costs.

Can the system support heavy industrial machinery and piping?

Yes, the design supports high-load conditions commonly required in industrial and infrastructure environments, including piping, HVAC systems, and heavy equipment.

Do these support systems comply with safety standards?

Yes, all components meet international standards and are compatible with seismic restraints, ensuring safe use in vibration-sensitive or high-risk environments.

Is welding required during installation?

No welding is required. The system uses bolt-connected components, allowing faster assembly and easier on-site configuration without specialized tools.

Can the system be reused for multiple projects?

Yes, components are reusable and adjustable, making them cost-effective for phased construction, expansion, or relocation requirements.

Are material options available for different environmental conditions?

Yes, options include galvanized, stainless steel, and aluminum to suit industrial, marine, chemical, and outdoor applications.