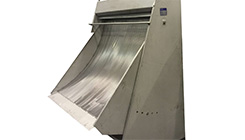

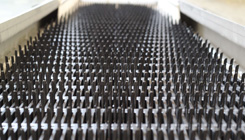

Travelling perforated screens are the equipment which are used for fine screening of solid materials by way of the perforations, which provide two dimensional screening process with the highest removal rates, and generally preferred to use in water and wastewater treatment plants. They have a capability of capturing the particles even in very small size and can be directly mounted in channels. This type of screen has a moving screen surface which continuously refreshes itself by travelling and, the components of screen last long due to this feature. Screen surface is automatically cleaned by nozzles which are located on outer surface of the screen panels. Because of the unique design of equipment, it is economically beneficial considering water and energy usage. On the other hand, the equipment has a high solid-liquid separation capacity by reason of its continuously cleaning ability, and it is well-suited for capturing the solids except the fibrous materials. As screening media, it has multiple perforated panels and operated as an endless loop. It is a well-known fact that central flow principle is the most effective way to remove suspended solid materials from liquid. Therefore, perforated screen panels are positioned parallel to the water flow. The water firstly enters the centre of travelling perforated screen, and then exits outward through both the ascending and descending perforated panels. Sismat Uluslararası Travelling Perforated Screens are mainly composed of frame, sprockets, drive shafts, screen panels, washing system and drive unit.

FEATURES AND BENEFITS OF SISMAT ULUSLARARASI TRAVELLING PERFORATED SCREENS

• Robust design and reliable operation

• High solid-liquid separation efficiency

• Minimum area requirement due to the compact design

• Suitable for use in deep channels

• Automatic cleaning mechanism

• Easily installed and retrofitted into any channels

• Low operation and maintenance cost

• Low energy consumption