Implementing Effective Partial Discharge Monitoring Solutions

The Continuous Partial Discharge Monitoring System plays a vital role in protecting high-voltage electrical equipment by identifying early insulation defects before they progress into major faults. With continuous data acquisition, operators gain reliable insights that help maintain electrical stability, reduce failure risks, and ensure long-term operational continuity.

Designed for high-dependency infrastructure such as substations, transformer stations, power plants, and industrial electrical networks, this system ensures uninterrupted performance while supporting proactive maintenance strategies. By detecting discharge patterns early, utilities and industries can avoid costly downtime and enhance planning efficiency for asset upkeep.

How the System Improves Electrical Network Reliability

- Provides non-stop monitoring for high-voltage equipment without disruption

- Uses advanced sensors to detect early insulation weakness and PD activity

- Enhances maintenance planning with real-time intelligence and reporting

Asset Protection Through PD Monitoring

- Helps identify failure risks early to prevent unplanned outages

- Enables online monitoring without shutdown or service interruption

- Strengthens reliability through long-term analysis and trend evaluation

Types

Online Partial Discharge Monitoring System

A permanent monitoring solution that continuously records PD activity during normal operation.

- No shutdown required for installation or data collection

- Ideal for transformers, switchgear, and HV cable systems

- Enables predictive maintenance with continuous analysis

Switchgear Partial Discharge Monitoring System

Engineered for compact and enclosed switchgear environments.

- Detects insulation degradation inside GIS or metal-clad compartments

- Improves reliability and prevents arc flash incidents

- Reduces unplanned downtime and switching failures

Transformer PD Monitoring System

Designed for power and distribution transformer monitoring.

- Identifies aging insulation, moisture ingress, or internal defects

- Works with existing transformer condition monitoring platforms

- Extends service life and reduces operational risks

Cable Network PD Monitoring System

Suitable for overhead and underground cable infrastructure.

- Detects discharge activity at joints, splices, and termination points

- Helps avoid cable corridor outages through early warning detection

- Supports long-distance HV transmission network monitoring

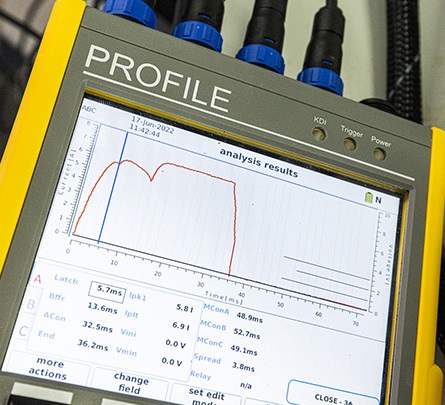

Portable Partial Discharge Testing Equipment

A flexible option for onsite verification and commissioning.

- Ideal for periodic inspections and quick diagnostics

- Helps assess equipment condition before permanent system deployment

- Useful for troubleshooting during shutdowns or field investigations

Standout Features & Benefits

Performance and Operational Value

- Enables early identification of insulation weaknesses before they escalate into serious failure or system shutdown.

- Improves predictive maintenance accuracy by combining real-time analysis with historical discharge trends and event classification.

- Minimizes unplanned downtime and operational disruptions through continuous monitoring and automated alert notifications.

- Enhances equipment lifespan by preventing repeated stress and deterioration caused by undetected insulation defects.

- Supports compliance with international reliability standards and safety protocols across high-voltage electrical networks.

- Reduces long-term maintenance and operational costs by enabling proactive intervention instead of reactive repairs.

Application Area

Typical Installation and Use Environments

- Utility substations and power transmission infrastructure

- Transformer stations across industrial and energy facilities

- Online monitoring for HV switchgear installations

- Cable networks supporting smart grid and utility operations

- Power plants and mission-critical electrical assets requiring continuous oversight

FAQ

How does Partial Discharge affect electrical equipment?

Partial discharge gradually damages insulation layers, leading to weakened dielectric strength. Over time, this increases failure risk, shortens equipment lifespan, and may cause unexpected outages.

Is continuous PD monitoring better than periodic testing?

Yes, continuous monitoring detects issues earlier than periodic testing because it tracks trends in real time, reducing uncertainty and enabling proactive maintenance decisions.

Can the monitoring system integrate with existing SCADA or asset management platforms?

Most modern systems support seamless integration with SCADA, DCS, and asset management software, enabling centralized monitoring and easier decision-making.

Does installation require shutting down equipment?

In most cases, installation and monitoring occur online, meaning the system can be deployed without interrupting normal equipment operation or power supply.

What industries commonly use continuous PD monitoring?

Utilities, oil and gas, renewable energy, manufacturing plants, rail networks, and data centers frequently use PD monitoring to ensure uninterrupted electrical performance.

How often does the system require calibration or maintenance?

Most systems require minimal maintenance. Periodic calibration checks, typically once or twice a year, help maintain long-term measurement accuracy.

Can PD monitoring help reduce operational costs?

Yes. Early fault detection helps prevent catastrophic equipment failures, minimize downtime, and optimize maintenance planning, significantly lowering long-term operational expenses.

What happens when abnormal discharge activity is detected?

The system immediately sends alerts or alarms, enabling maintenance teams to investigate causes, evaluate severity, and take corrective action before failure occurs.