Reliable & Flexible Solutions for Pipe Systems

At Dutco Tennant LLC, we provide high-performance metallic expansion joints sourced from leading global manufacturers such as Lonestar Industries. Our solutions are trusted across the UAE and GCC for managing thermal expansion, vibration, misalignment, and movement in industrial piping systems.

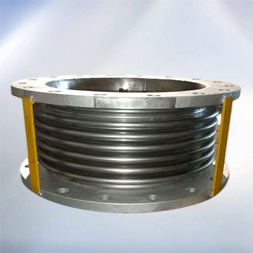

Metallic expansion joints, also known as metal bellows expansion joints, are flexible connectors installed in pipelines to absorb dimensional changes caused by temperature variations, vibration, and dynamic forces. They reduce mechanical stress, prevent structural damage, and extend the operational lifetime of pipelines and connected equipment.

Our range of pipe expansion joints is designed to accommodate demanding industrial conditions, including high pressure, extreme temperatures, and corrosive environments. These joints are engineered for long service life, reliability, and easy integration into complex piping systems.

With applications across oil and gas, power generation, petrochemical, water treatment, and district cooling industries, our metal expansion joints provide a dependable solution to maintain pipeline integrity and operational efficiency.

Why Choose Our Expansion Joints

Our metallic expansion joints are engineered to deliver reliable, long-lasting performance across diverse industrial applications. They are ideal for systems requiring high flexibility, durability, and precise movement absorption.

- Engineered for extreme temperature and pressure conditions

- High-quality materials ensure long-term durability and corrosion resistance

- Customizable designs for specific pipeline layouts and industrial requirements

- Minimize maintenance costs and extend the operational life of connected equipment

- Reduce vibration, mechanical stress, and noise for smoother system operation

Product Highlights

- Strong build quality using stainless steel and high-strength alloys

- High pressure and temperature resistance for industrial pipeline systems

- Excellent corrosion and fatigue performance for long-lasting durability

- Vibration dampening helps stabilize pipelines and reduce system noise

- Custom-engineered solutions for flexible metal expansion joints and bellows

- Reliable performance in oil and gas, petrochemical, district cooling, and HVAC networks

Standout Features & Benefits

Enhanced System Stability

- Absorbs thermal expansion and contraction to prevent pipeline stress

- Maintains alignment and sealing integrity under multidirectional movement

- Reduces the risk of mechanical failures in critical industrial systems

Durable & Corrosion-Resistant Design

- High-grade stainless steel and alloy construction withstands harsh environments

- Long-lasting performance even under extreme temperature and pressure

- Supports industrial and commercial pipelines for years of reliable operation

Vibration & Noise Control

- Damps vibration to minimize operational noise

- Protects connected equipment from mechanical shock

- Improves system efficiency and longevity of the pipeline network

Application Area

Pipeline Applications Across Sectors

- Oil and Gas: Refineries, offshore platforms, and pipelines requiring thermal movement absorption

- Power Generation: Turbine piping, boilers, and heat exchangers with temperature and pressure shifts

- Petrochemical and Chemical Processing: Resistant to corrosive chemicals and high-temperature flows

- Water and Wastewater Treatment: Desalination and sewage plants absorbing vibration and system movement

- HVAC Systems: Chilled and hot water systems in commercial and industrial buildings

- Marine and Shipbuilding: Engine rooms and exhaust systems subjected to motion

- Steel, Cement, and Mining: Abrasive and high-temperature ducts requiring bellows protection

- District Cooling & Heating: Long pipelines experiencing thermal expansion

- Food, Beverage, Pharmaceutical & Biotech: Hygienic systems needing vibration control

- Building & Infrastructure: Bridges, tunnels, and structural expansion points preventing deformation

FAQ

What materials are used in metallic expansion joints?

Metallic expansion joints are typically constructed from high-grade stainless steel or specialized alloys to provide resistance against corrosion, fatigue, high temperature, and mechanical stress in pipelines.

Can these joints absorb multidirectional movement?

Yes, flexible metal expansion joints are engineered to accommodate axial, lateral, and angular movement while maintaining sealing integrity across complex pipeline layouts.

How do expansion joints help reduce pipeline stress?

They absorb dimensional changes caused by thermal expansion, vibration, or pressure fluctuations, preventing mechanical failures and extending the lifespan of pipelines and connected equipment.

Are metallic expansion joints suitable for chemical industries?

Absolutely, stainless steel and alloy-based expansion joints withstand corrosive chemicals, high temperatures, and abrasive flows, making them ideal for petrochemical and chemical processing plants.

Can they be used in HVAC systems?

Yes, flexible and tied expansion joints are used in chilled and hot water systems to reduce vibration, noise, and thermal stress, enhancing overall HVAC performance.

What industries benefit the most from metallic expansion joints?

Oil & gas, power generation, petrochemical, water treatment, HVAC, marine, steel, cement, food, pharmaceutical, and infrastructure sectors rely heavily on expansion joints for reliable pipeline operation.

How is vibration and noise controlled with these joints?

The bellows structure and high-strength materials dampen mechanical vibrations and system noise, protecting both pipelines and connected machinery.

Can these joints be customized for specific applications?

Yes, Dutco Tennant offers custom-engineered solutions tailored to pipeline size, movement range, pressure requirements, and industry-specific needs.