Expansion joints are used in piping systems to absorb thermal expansion or terminal movement where the use of expansion loops is undesirable or impractical. Expansion joints are available in many different shapes and materials. A bellows is made up of a series of convolutions, with the shape of the convolution designed to withstand the internal pressures of the pipe, but flexible enough to accept axial, lateral, and angular deflections. Expansion joints are also designed for other criteria, such as noise absorption, anti-vibration, earthquake movement, and building settlement. Pipe expansion joints are also known as "compensators", as they compensate for the thermal movement.

The type of Expansion joint are Metallic, Rubber & Teflon Bellows.

The expansion joints are used in various facilities, such as petrochemical complexes, electric power plants, steel plants and chemical plants. Combinations of expansion joints can be used as earthquake-proof piping for seismic isolated structures

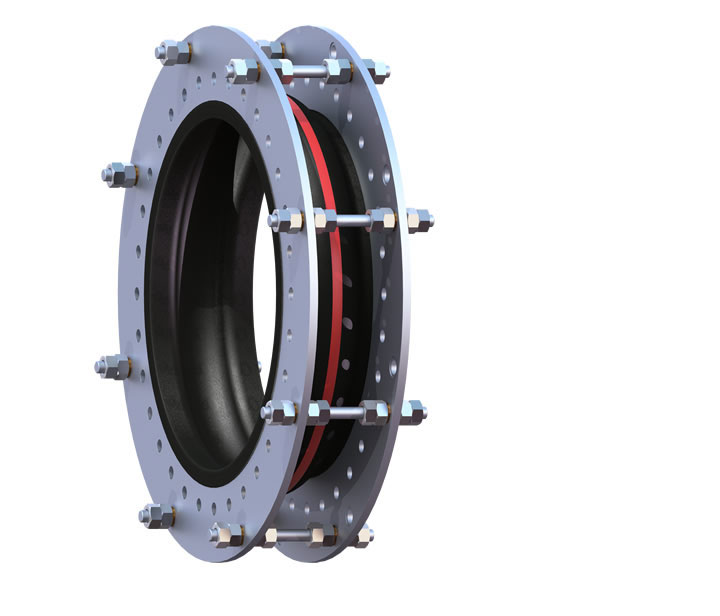

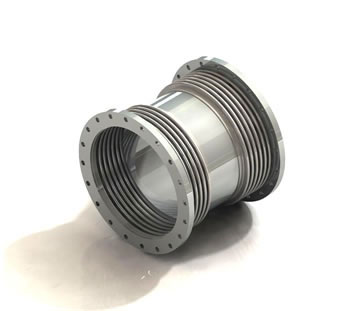

Rubber & Metal Expansion Joints

- Size : 2” to 40” - Rubber Bellows

- Size : 2” to 24” – Metal Bellows

- Working Pressure PN6/ PN10/ PN16

- Floating Flanges

- Corrosion & Erosion Resistance

- Low Deformation under Pressure

- Absorbs Axial, Lateral & Angular Movement

- Design Std /Testing Std: As per Manufacturers Standard

- End Connection: Welded Ends/ Screwed Ends/ Flanged EndsDrilling to ANSI/ DIN/ JIS Standard

- Bellows : Reinforced Neoprene Rubber/SS316/ Inconel 625

- Flanges: Carbon Steel / Stainless Steel with Galvanized

- Tie Rods

- Other material suitable for the required application

- Higher Sizes