DIFFERENCE BETWEEN CAST IRON VALVES AND DUCTILE IRON VALVES

Customers from several types of industries look for valves of several varieties for their high demand processes. Valves are found in a wide number of materials for any type of application that can be imagined. A few of these materials are carbon steel, PVC, stainless steel, ductile iron, and cast iron. In this post, we will be focusing on two of those materials which are ductile iron and cast iron. There has been a huge argument for choosing the best option among ductile and cast-iron valves which has been prevalent for several years as everyone is not aware of their differences.

Comparing valves made out of cast iron and ductile iron is simple as both of these materials have just a few major differences. So here is an outlined property of both materials and also the pros and cons of each.

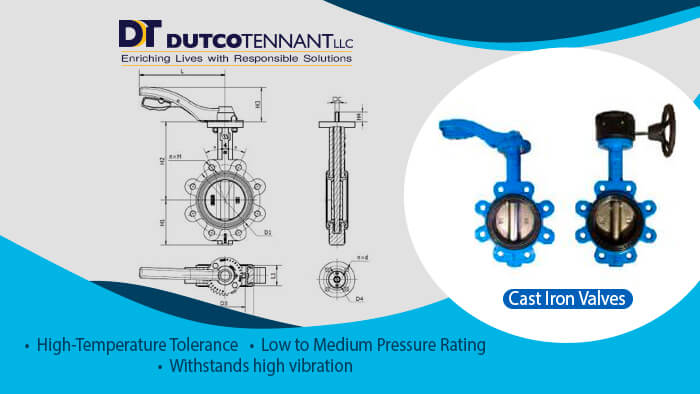

Cast Iron Valves

Cast Iron or gray iron is a type of metal that has been in use for several hundreds of years. It is an allow that is made from 96%-98% iron, 2%-4% carbon, and trace amounts of silicone. It has impressive tolerance to temperature with some cast iron being capable of handling temperatures over 2100F (1150C). In the case of pressure, cat iron’s strength mainly depends on the pressure class. The two most common ones are class 125 and class 250. At less extreme temperatures, class 123 cast iron flange is rated for a pressure level between 150 and 200 psi. The class 250 cast iron is a little bit tougher and has pressure ratings from 300 to 500 psi. These pressures can vary according to the type of the end. Cast iron is much stronger and will usually not have any damages even after experiencing intense vibrations. The main drawback of cast iron valves is that they are not at all ductile. Bending virtually will cause cracking of the cast iron and it will become much useless. One amazing quality of cast iron is that it not that expensive. Cast iron is the most economical option among the metal which makes it a great alternative for people looking for budget-friendly options.

Ductile Iron Valves

Ductile Iron has amazing tensile strength, corrosion resistance, and yield strength. Alike cast iron, ductile iron does not break when it is bent so it is much more suited for high demand applications. Ductile Iron is a strong and reliable material for fittings, pipes, and valves. One drawback of this is the pricing. Ductile Iron is comparatively more on the expensive side than cast iron because of its more complicated chemical makeup. If your application needs a tougher material, then you may need to spend comparatively more.

Deeper Comparison

Now that you have learned and understand both of these materials, now we have made a deeper breakdown of the differences between both of these metals. This will give you a much clear and easier understanding.

Durability –

Cast Iron is extremely strong and can handle much higher pressure than any plastic. When the rated pressure of a cast iron valve or pipe exceeds, it can get cracked or bent. Cast iron has much zero ductility which makes it extremely rigid and can get cracked if it is bent. Over the period of time, cast iron can also attract rust and it needs regular maintenance to keep the valve clear of any corrosion.

Ductile iron has impressive integrity of the structure and can handle high temperatures and pressures without flinching. This is because of the ductile nature which makes the material much less likely to get bent or cracked. Ductile iron will also attract rust over the passing of time.

Ease of Installation –

Both Cast and Ductile Iron valves offer the users a wide range of installation options. The cast iron valves are bolted using flanges and the same is for ductile iron. Welding is not recommended.

If you are looking for a comprehensive range of Cast Iron Valves for your plumbing projects in the Middle East then you can definitely find them with Dutco Tennant LLC. We are the largest supplier of Cast Iron valves from the house of WATTS. Our offerings include Butterfly valves (Lugged type, Wafer type), Strainers, Check valves, Gate valves & Globe valves.