Understanding The Role Of Expansion Joints In Preventing Water Ingress

It may not be visible, but every massive structure, like buildings or bridges, are always prone to movement caused by expansion and contraction of materials or variable load stress. These subtle movements may lead to cracks or leaks, making way for water to ingress and degrade the structure eventually.

That’s why expansion joints are integrated into such constructions. These absorb movements of building components and stop the entry of water, keeping the structures stable, resilient and long-lasting.

The Role Of Water-Tight Expansion Joints

Every building material, like concrete, steel, tiles, etc., reacts differently to temperature and load changes. If not absorbed, their movements lead to hairline cracks, especially where floors, walls and ceilings meet. And even the smallest gap can create a way for water to seep through, sometimes leading to irreversible structural damages.

Expansion joints are controlled gaps that stop this from happening. They act as bridges between separate building components, helping them move freely without causing cracks and leaks. By expanding and contracting with the elements, the expansion joints prevent the entry of moisture or debris. This is how they maintain the structural integrity of the building as well as its freedom.

How Expansion Joints Evolved Through The Years

The idea that buildings move under heat or load stress is not a new thing. Thousands of years ago, In ancient Greece or Rome, people used to incorporate expansion joint gaps in stone aqueducts and masonry walls to control such movements.

However, the first proper waterproof joint came much later, in the earlier 20th century. With the advent of more complex and concrete structures, reliable movement control became a necessity.

Engineers developed rubber, polymer, and metal joints to preserve structural integrity of buildings. Now, in the Middle-East, temperature and pressure changes are quite common. Hence, expansion joints are one of the key components in construction. The modern-day innovative joints not only maintain building integrity by absorbing movements but also stops water ingress by preventing the formation of cracks altogether.

The Engineering Innovation Of Water-Tight Joints

While the design of expansion joint profiles may vary in different regions, the engineering and mechanism remains the same.

A few common elements include:

The Core Materials

Most expansion joint profiles are composed of rubber, high-quality polymers or EPDM (Ethylene Propylene Diene Monomer). These materials don’t crack or tear due to high environmental stress or major expansion and contraction.

Edge Protection

The edges of expansion joints are covered in durable materials, like aluminum or steel that safeguards them from mechanical damages and wear.

Water-Resistance

Expansion joints are not water-tight by default. Sealants and primers, like resin, silicone and polyurethane are used to make them water-tight and leak-proof.

Tapes And Rods

Before applying the sealants, tapes and backer rods are placed to prevent them from sagging or sinking. These also ensure that the sealants are applied at the right depth and encourage seamless movement due to expansion and contraction.

The entire process involves:

- Proper cleaning of the substrate.

- Placing them in lines.

- Compressing and curing.

Such preparations help form water-tight, permanent expansion joint profiles that support movement of the building components.

Preventing Water Ingress - The Engineering Marvel

Now, how do these joints actually prevent water from entering building components?

That’s another design wonder. Let’s break it down.

Step 1: Creating the controlled gap

A proper gap is created between the structural elements, like floors, walls and ceilings. This gap helps the building components to move under temperature or load stress.

Step 2: Sealing the gap

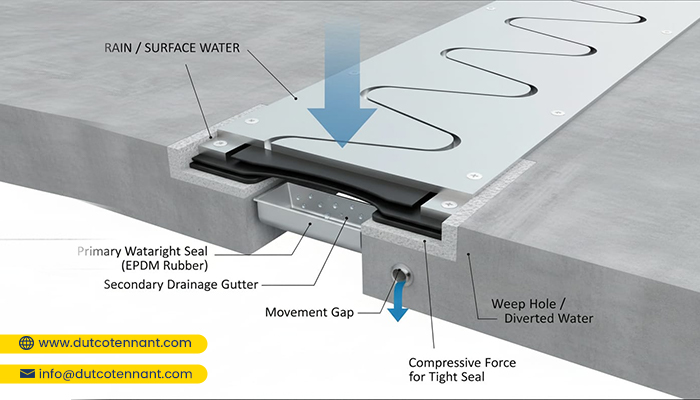

Using rubber, polymer or other resin-like substance, a sealant is installed into the gap. It’s held in place with stainless steel or aluminum edges that also protect the seal from wear in the long run.

Step 3: The water barrier explained

The elastic seal along with its supporting edges create some kind of a watertight membrane across the joint gaps. It acts as a continuous barrier against rain, groundwater or cleaning water that tends to seep through the joints and damage the structure.

Step 4: Moving with the structure

These joints enable seamless movement of building components by compressing and stretching under environmental heating and cooling respectively. The seal remains intact, thus preventing water ingress during such movements.

Apart from these functions, the metal expansion joint profiles also stay strong under mechanical impacts, like seismic vibrations, load stress caused by vehicles and foot traffic. UV and corrosion-resistant materials also prevent long-term damages caused by sunlight, moisture and heat.

Areas That MUST Install Water-Tight Expansion Joints

You should note that every construction requires these joints as mandatory. However, their purposes vary from one structure to another.

A few applications for watertight joints are:

- Bridges and dams - For absorbing movements caused by temperature changes or seismic vibrations and preventing water entry through cracks. In dams, these joints maintain hydraulic tightness besides enabling movement of large concrete structures.

- Walls of buildings - Prevention of rainwater and atmospheric moisture from seeping into the facades and internal walls.

- Floors of commercial and industrial spaces - Stainless steel expansion joints in these areas are necessary to prevent wash-water and cleaning solutions from penetrating tiles and slabs.

- Swimming pools - Expansion joints are also installed in swimming pool boundaries to prevent water from damaging the surrounding areas.

What Options Do You Have In Expansion Joints?

Although the role of expansion joints in different areas may be similar, their design and construction may still vary based on specific purposes.

In common cases, you may have the option to choose from:

- Heavy-duty joint profiles for areas with large vehicular movement, like forklift crossings

- Watertight expansion joints for wet or moist areas to prevent water ingress as explained above

- Seismic profiles for buildings or construction structures in regions susceptible to earthquakes and other vibrations

- Flush-mounted systems for easy application on the interiors of any building

Each type helps serve a specific role based on the structure and the region where it’s located. For example, the products that we deliver enable absorption of excessive mechanical stress besides preventing corrosion due to water ingress.

Ensuring Longevity By Preventing Water Seepage

At Dutco Tennant LLC, we tend to consider dampness as the ‘slow decay’ of any structure. That’s because the degradation is not visible at first, but when it continues, the entire structural integrity of the building is compromised. With the help of watertight joints, we can prevent this from happening.

Our range of stainless steel joints are ideal for large buildings, dams, bridges and other concrete and metal structures. With exceptional design, sealing and flexibility, these joints ensure longevity of such massive structures by supporting movement and preventing water ingress.

If you need to share more details about the type of infrastructural project you're handling, we can curate a customised system to meet your requirements. Get in touch with our sales team and choose your expansion joint profile today.