7 Effective Ways To Control Floor Movements In Buildings

There are various reasons for building floor movements, like heat and temperature changes, seismic vibrations, and load stress, which make floor materials expand and contract. If not controlled, these ‘apparently harmless’ movements can result in cracks, loose tiles, water ingress, all of which contribute towards lowering the lifespan of your building floors.

One of the essential aspects of modern floor designs is to control these movements and prevent water seepages. While you cannot ‘stop’ the floors from moving, you can always regulate and control such shifts with the right engineering solutions.

1. Choosing The Right Movement Joint Gaps

Movement control joints are intentional gaps that absorb thermal and structural shifts of building floors. Installed at proper intervals, generally 16-30 metres, these joints help relieve stress during expansion and contraction of flooring materials.

It’s best to choose stainless steel or aluminum movement joints to suit varying environmental and load conditions. Airports, factories or shopping centres, these joints also serve the function of preserving floor surfaces from cracks or tile damages.

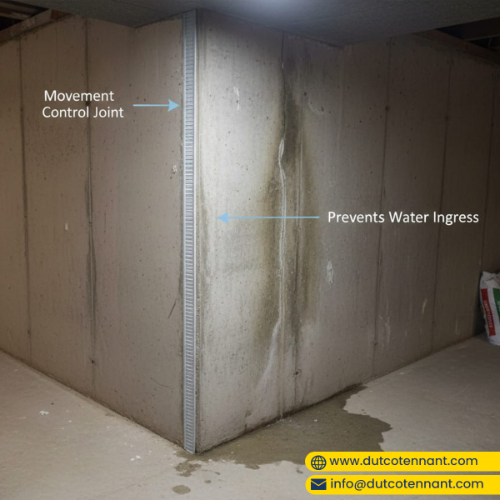

2. Water-Tight Movement Joints For Moist Surfaces

Water-tight joints are meant for moist surfaces, like basement floors, tunnels or podium decks that are generally prone to water damages. Conventional joints can weaken over time, as these surfaces remain damp due to long-standing or running water.

Using hydrophilic sealants and moisture-resistant primers, these movement control joints secure structural movements of surfaces without risking water ingress. Metal profiles with flexible rubber or polymer inserts between two flooring sections help prevent water seepages, corrosion or mould formation.

3. Install Movement Joints On Tiled Floors

Tiled floors are susceptible to major structural damages, chips and cracks due to floor shifts. Installing the joints between the slabs can help absorb stress and preserve expensive tiled floors.

Products made of stainless steel, brass, aluminum or even PVC seamlessly absorb expansion and contraction of tiled floors. With coated finishes, these joints are resistant to oils, acids and abrasive agents used to clean tiles.

4. Ensure Proper Joint Spacing Between Tiles

A poorly-planned layout leads to improper joint spacing on tiled floors. It doesn’t matter how effective the movement joint is, such layouts cannot help control expansion or contractions.

For indoor applications, movement joints should be placed every 4-6 metres to perform successfully. But for outdoor applications, placing them every 3-4 metres is ideal.

Note: These joints should also be aligned with building expansion joints beneath the surface. It helps maintain consistent performance across all layers of the building floor system. Expansion and contraction can be seamless without the tiles or their edges to chip or disintegrate.

5. Protect Floors From Load Changes And Vibrations

Floor movements are caused by thermal impacts, as well as constant vibrations from forklifts, trolleys, and rolling loads in industrial settings. This variable load pressure is transferred to tiles and slabs, making them grow cracks over time.

Heavy-duty movement control profiles are designed to absorb this excess load. With thicker edges, layers of inserts and high static resistance, these joints can handle massive loads and absorb the vibrations before they reach the tiles. Ideal for storage areas, warehouses and parking facilities, these systems help maintain structural stability besides preserving tiled surfaces.

6. Maintain Moisture And Temperature While Installing

Proper temperature and moisture conditions are crucial even during installation of the profiles. For example, premature curing or excess humidity can trap the stress within the system, leading to problems later.

If you are installing movement joints indoors, proper room temperatures should be maintained and moisture barriers between tile layers are compulsory. When installing outdoors, avoid placing in direct sunlight, as thermal conditions can cause tiles to shift before the adhesive settles in. The chances of internal tension can be reduced while installing joint profiles between tiles or slabs by following some simple precautions.

7. Regularly Inspect The Joints For Signs Of Repair

Just installing these systems across a flooring system won’t help it remain stable in the long term. You have to keep inspecting it for even minor signs of injury or load stress.

Further, joint inserts can harden over time, seals can get detached from the surfaces or profiles can lose elasticity under load stress. Check for these issues from time to time to ensure proper stability of the entire flooring system.

Movement Control Joints For All Flooring Systems

The materials in your flooring system will expand and contract under mechanical or environmental stress. This is inevitable. But the effectiveness of a movement joint profile lies in how well it absorbs such movements without putting stress on the flooring components, like tiles or slabs. Proper design profiles, right kind of sealing, adequate spacing between joints and expert installation all combine to give a system that stands the test of time.

At Dutco Tennant LLC, we can deliver top-quality solutions for your flooring systems. For decades, we have been supplying the same to a range of industrial units, luxury hotels, villas, resorts, institutes, malls and warehouses. These are some common places that require tight profiling to absorb floor movements. Our custom profiles make sure your floors maintain their integrity for years to come.

Get in touch with our sales team to discuss your project requirements.