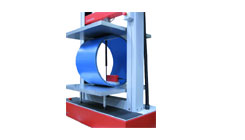

Box compression tester with integral Pc and software dedicated to testing corrugated board boxes and cartons. Box Compression Tester is a consistent tool to indicate the compression strength of cardboard boxes to make sure that it does not gets deformed or crushed when stacked one above the other during storage or transit. The box is placed on a flat platform and pressed downwards from the top with the help of motorized arrangement and in this way the compression strength is determined. Box Compression Tester is designed to quantify box or container performance so that the effect of various board mediums, closures, and interior partitions can be plainly compared by means of Load & bend analysis. The box compression testers supplied by us are manufactured to meet the requirements of the paper and packaging industries according to international standards. It is designed ergonomically and is easy to use. Our Compression Tester is used to measure the box compression strength, shape change and stacking capability of cartons, beehive crates, paper tanks, paper cases, etc. Box Compression Tester is designed to evaluate compression strength of the corrugated box and the load range selected to completely collapse as peak load or maybe with a pre-determined load for a given period to evaluate stacking load. Compression Strength Test also serves as a useful index of overall quality of the material and workmanship of the box.

- Construction – Rigid Moving platen driven by 4 recirculating ball screws. Platen parallelism better than 1:4000. Load readings are taken from an average of 4 balanced load cells to compensate for the effect of any off-center loading.

- Force Measurements –Universally Calibrated, better than Grade 0.5 EN 7500-1, DIN 51221 ASTM E-4. AFNOR A03-501. Range 0.4% to 100% minimum. Automatic identification of load cell. Resolution 1 part in 500000 with auto-ranging. Electronic load cell protection.

- Extension Measurements – Full frame length to 0.001mm. Resolution 0.001 min. Accuracy 0.01mm. Absolute, relative and auxiliary modes mm, inch and percent. Programmable extension limits.

- Speed Control – Drive system temperature and current protection. Positional jog speed 0.001mm/min to the maximum. Speed setting increments 0.001mm/min.

- Load Frame – Rigid frame, using dual slide crosshead guidance system and rigid extruded support column. Frame stiffness 5kN/mm plus K factor facility built-in. Recirculating ball screw with bellows. Electronic limit trips, total travel trips, and customer programmable safety stops. Rubber mat front protection.

- Software – Comprehensive winTest™ Analysis universal windows software covering tensile, compression, peel, shear, tear, cyclic, creep and multi-stage testing. It includes a wide range of industry-standard test methods and facility to create and store an unlimited number of further test methods. There is automated storage of all test data and ease of export to other software packages such as word, excel, access and SPC systems for enhanced report generation.

Features

- SPEED CONTROL : Drive system temperature and current protection.

- LOAD FRAME : Rigid frame, using dual slide crosshead guidance system and rigid extruded support column. Electronic limit trips, total travel trips and customer programmable safety stops. Rubber mat front protection.

- SOFTWARE : There is automated storage of all test data and ease of export to other software packages such as word, excel, access and SPC systems for enhanced report generation.